Selecting raw material of CNC machined parts.

It is important for engineers to choose material of CNC machined parts, then desinging products. Selecting the right material can save your time and money on your next job.

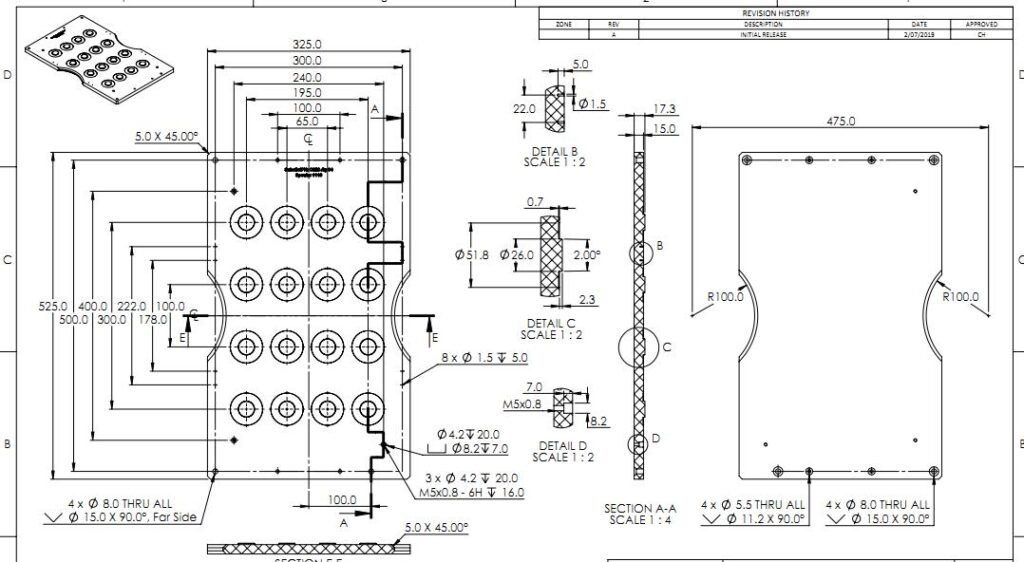

Last year, we received a order of some delrin products,there was a plate with many holes, size:525x325x15mm. We did our best to machining it by CNC miller, but get a big deformation after finish. Even there is no flatness note on drawing, but it is out of 0.5mm, we don’t think it can be used, after communication with customer, they only can use within 0.1mm flatness.

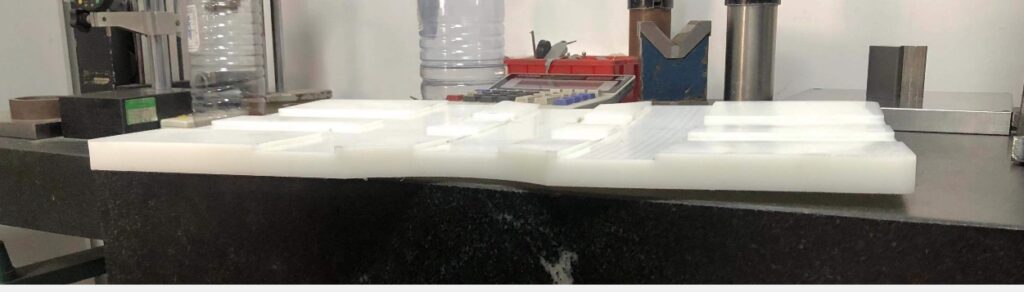

We rebuilt this delrin plate again.we know that the large internal tension of Delrin, in order to prevent the stress and deformation.

1. We did heat treatment,to eliminate the internal stress before machining.

- Machining the plate by several steps, and keep long time between each steps,to give enough time for cooling the temprature of the workpiece.

But it’s also faild at the second time, for this dimension of plate, 525x325x15mm,not suitable for cutting many holes on it. The plate was deformed during the process of milling holes. Finally,we don’t want to waste the customer’s time,showing the fact and asking for cancelthe order.The customer also understand us.

Almost one week later,the customer ordered another similar plate with Aluminum from us, we completed this job as well this time.

Related reading: Selecting correct tolerance for your machined components