There are many deburr types for machined part.

Deburring is an essential step in the production of machined parts. It refers to the process of removing unwanted burrs, which are rough edges or protrusions that form on the surface of machined parts during the manufacturing process. Removing burrs is important because they can affect the performance, safety, and appearance of the finished product.

There are several common types of deburring for machined part:

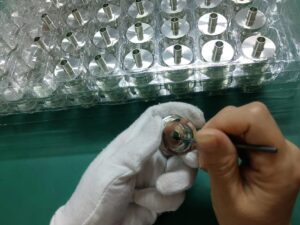

– Manual deburring: Hand-held tools are used to remove burrs from the parts. This is a labor-intensive process that requires skilled workers to ensure that the burrs are removed without damaging the parts.

– Vibratory deburring: Parts are placed in a vibratory bowl with abrasive media, which removes burrs and improves surface finish. This process is faster and more consistent than manual deburring and can handle large volumes of parts.

– Thermal deburring: Parts are heated and then cooled rapidly, causing burrs to break off. This process is suitable for parts with complex shapes and internal cavities that are difficult to reach with other methods.

– Electrochemical deburring: An electrolyte fluid and electric current are used to selectively dissolve burrs from the parts. This process is highly precise and can be used to deburr parts made from a variety of materials, including stainless steel, titanium, and aluminum.

Choosing the right deburring method depends on several factors, including the size, shape, and material of the parts, as well as the desired finish and tolerances. Each method has its own advantages and disadvantages, and a skilled deburring operator can help determine the best approach for a particular application.