7 steps of completed machined parts

Some customer couldn’t understand that why it take long time to complete machined parts. Precision machining is different from 3D print, that we can get complete product as soon. Machining of parts is a process where a piece of raw material is cut to fit requirement.

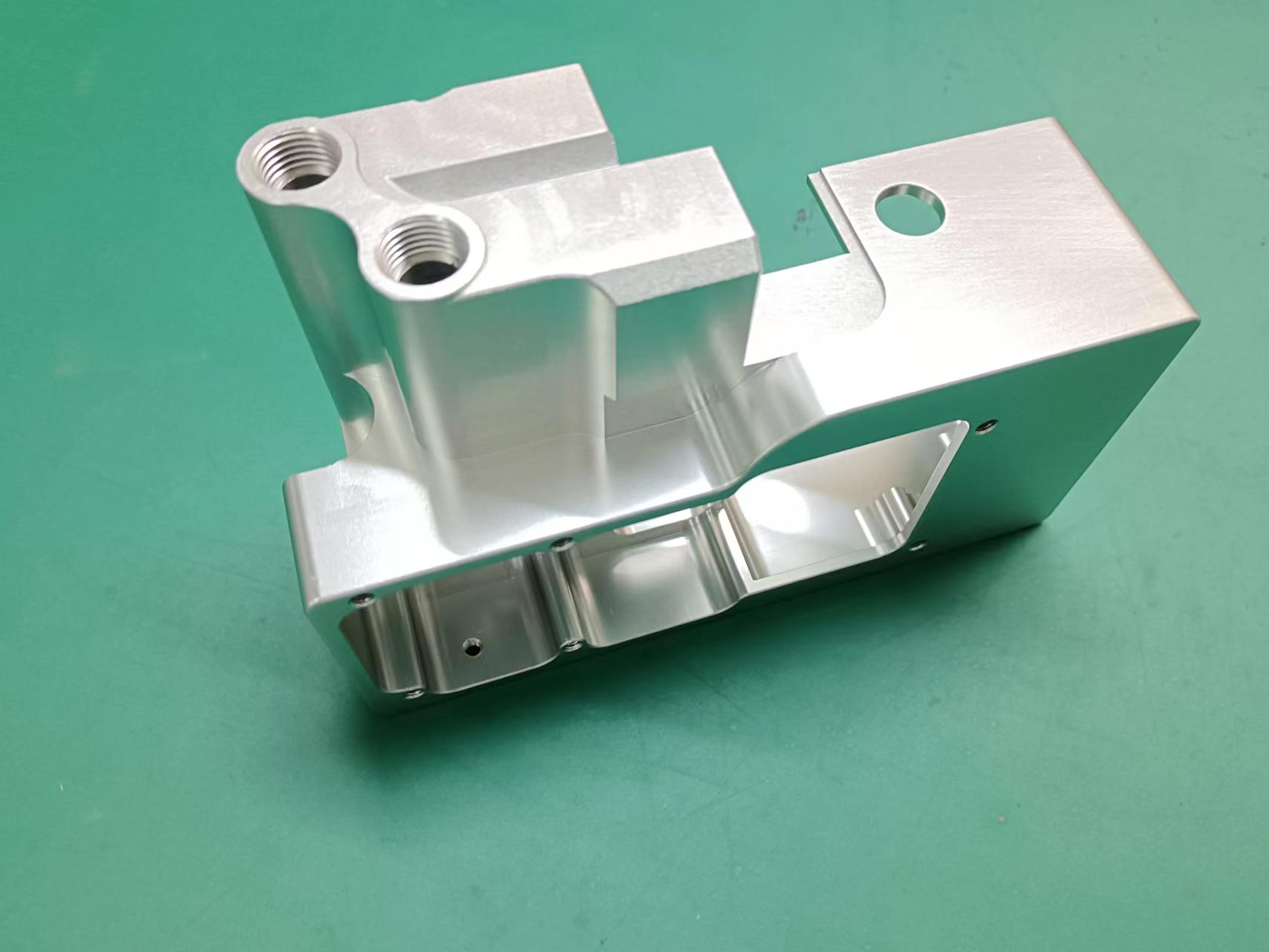

Actually, the final shape and size is through material removal. The completed machined parts would be done by several machining steps.

1. Cutting raw material

Because we always get raw material in the market as different shape, such as bar of 6 meter in length, plate of 1×2 meter. According to the drawing, we should cut the raw material to small pieces, the size is suitable for next machining process.

2. Roughing

Since the cutter feed can not be so much, we can not remove the material and meet to precise dimensions at one step. So roughing is usually the first step in machining. It is to remove blank allowances quickly. There are turning and milling process.

3. Finishing

Roughing often get poor finish, inaccurate dimensions, so we need finishing after roughing in machining. According to the shape and tolerance requirement, we should choose turning, milling, grinding, wire cutting and EDM. We even have to use CNC machining to complete some complex machined parts.

4. Deburrs and cleaning

After finishing, there are a lot of burrs and oil stains on the machined parts. Sometimes we need to move burrs by hand, especially for some small machined parts. At SYM precision machining, we usually use ultrasonic cleaning and dry the parts by oven. So you always can get very clean machine parts from SYM.

5. Heat treatment and surface treatment

For some requirements of hardness of mahined parts, we should send the parts outside of factory, there are professional cooperators who is specialised in heat treatment. It takes 3-5 days. The situation of surface treatment is same as heat treatment. Here is rare to find a machining factory who can handle both heat treatment and surface treatment in house.

6. Quality checking (QC)

Quality checking is very important during the whole machining process. So checking the size of raw material, material analysis, and checking the size of machined parts at every machining step. Finally, we have to check all dimensions and appearance before packing process.

7. Safe packing

This is the final step of machined parts, we can not ignore this step. In order to avoid the parts damage during transportation, we should find a good way to protect all machined parts as well.

From all above, you can see that is difficult to get machined parts in 2 days. So at SYM precision machining, our common delivery time is 7-15 days. It is also can meet 3-5 days for some sepcial case.