Interference fit is a common way of mechanical connection, about the tolerance of interference fit, it is different from plastic machining part and steel parts. If the magnitude of interference is too large, the plastic parts easy crack under press fitting.

Let’s explain some details of acctual case, which happened at SYM Precision Machining Shop.

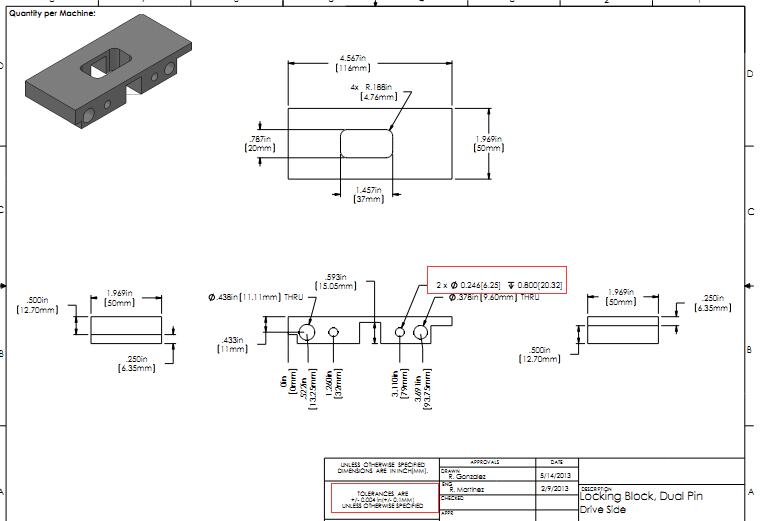

Look at the picture of drawing as below,we always complete the machined parts according to customers’ drawing.

Material: PVC

There are two holes on side surface, for press fitting a dowel PIN.

Hole size: 6.25mm

Pin size: 6.35mm

There is no precise tolerance for these two holes. We comply the tolerances +/- 0.1mm, and make the hole to 6.15-6.35mm as well, unless otherwise specified.

First time, we drilled the holes close to the lower tolerance, 6.15-6.25mm. The result of assembly work is that plastic parts were cracked.

At the second time, we made the holes close to the upper tolearance, 6.3-6.35mm. The assembly work is going as well without any issue.

Therefore, in order to reduce the machining issue.

First of all, we should mark the dimension with tight tolerance for press fitting, while we designing products.

On the other hand, the machining manufacturer must very professional.

SYM Precision Machining, 23 years of precision machining experience. We can always learn from a variety of different issues, learning record, continous improvement, to provide customers with better precision machining solutions.