5 major errors in metal machining processes

You will learn more about metal machining processes from this article.

The machining error reflects the accuracy of metal machining processes. If a mechanical processing factory wants to ensure the quality of products, the first thing to do is to control the machining errors. What are the common machining errors in actual production? Let’s talk about it in detail.

1.The manufacturing error of machine tools

The manufacturing error of machine tool mainly includes spindle rotation error, guide rail error and transmission chain error.

The spindle rotation error refers to the change of the actual rotation axis of the spindle relative to its average rotation axis at each moment, which will directly affect the accuracy of the machining parts.The main reasons for the spindle rotation error are the coaxiality error of the spindle, the error of the bearing itself, the coaxiality error between the bearings, the winding of the spindle and so on.

The guide rail is the benchmark for determining the relative position of each machine tool component on the machine tool, and it is also the benchmark for machine tool movement. The manufacturing error of the guide rail itself, uneven wear of the guide rail and installation quality of are the important factors that cause the guide rail error.

The transmission chain error refers to the relative motion error between the transmission components at the beginning and end of the transmission chain. It is caused by manufacturing and assembly errors in each component of the transmission chain and wear in the process of use.

2.The geometric error of cutting tools

Any tool in the cutting process is inevitable to produce wear,which will cause the size and shape of machining parts to change. The influence of geometric error of cutting tool on machining error varies with different types of cutting tool. The manufacturing error of the cutting tool will directly affect the machining precision of the parts when the cutting tool is used for metal machining processes.

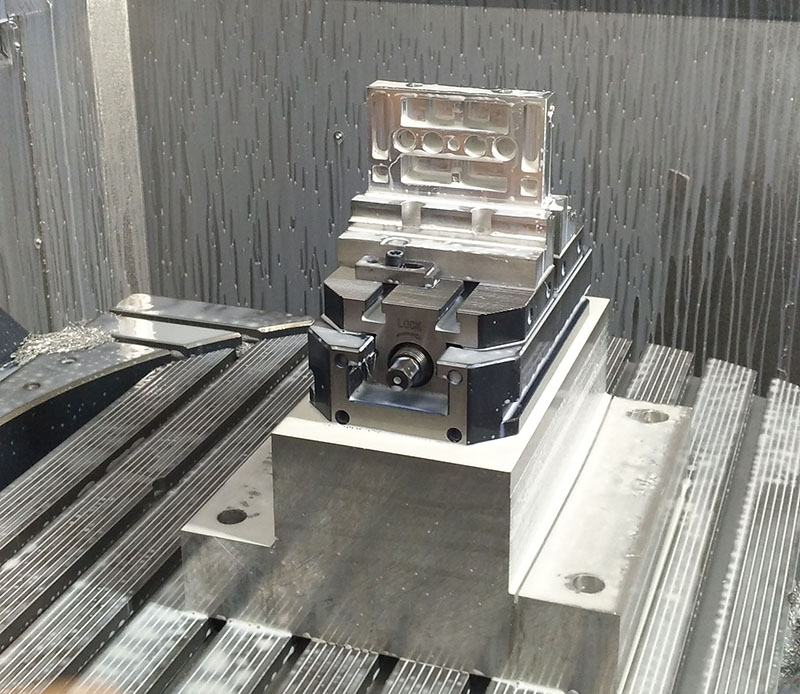

3.The geometric error of fixtures

The function of the fixture is to make the parts have correct position, so the geometric error of the fixture has a great influence on the metal machining error,especially the position error.

4.The positioning error

The positioning error mainly includes the reference misalignment error .When the part is processed on the machine tool, several geometric elements on the part must be selected as the positioning datum during the processing. If the selected positioning datum does not coincide with the design datum, the reference misalignment error will occur.

5.The error caused by stress deformation of the process system

Part stiffness: In the process system, if the part stiffness is relatively low relative to the machine tool, cutting tool, and fixture, under the action of cutting force, the deformation caused by insufficient stiffness of the part has a great influence on metal machining error.

Cutting Tool stiffness: The external turning tool has a large stiffness in the normal direction of the machining surface, and its deformation can be ignored. Inner bore with small boring diameter, the stiffness of the cutting tool rod is very poor, so the deformation of the tool rod has a great influence on the accuracy of the hole processing.

Machine parts stiffness: Machine parts are composed of many parts. Factors that affect the stiffness of machine parts include the influence of contact deformation of the combined surface, the influence of friction, the influence of low stiffness parts, and the influence of gap.