PEEK Plastic CNC Machining: A Guide to Advanced Polymer Precision

Learn everything about PEEK plastic CNC machining — from material advantages, machining process, applications, tooling, to expert tips for flawless results. Introduction to PEEK Plastic CNC Machining PEEK plastic CNC machining represents the intersection of material science and modern engineering. This process unlocks the full potential of one of the world’s most advanced thermoplastics, offering […]

Expert Guide to Precision Titanium Machining

At the heart of all these processes, technologies, and decisions lies precision titanium machining — the combination of engineering expertise, advanced machinery, and skilled operators that turn raw titanium into mission-critical parts. It’s a craft that requires patience, planning, and continuous improvement. Whether you’re making a bone screw or a rocket nozzle, precision matters — […]

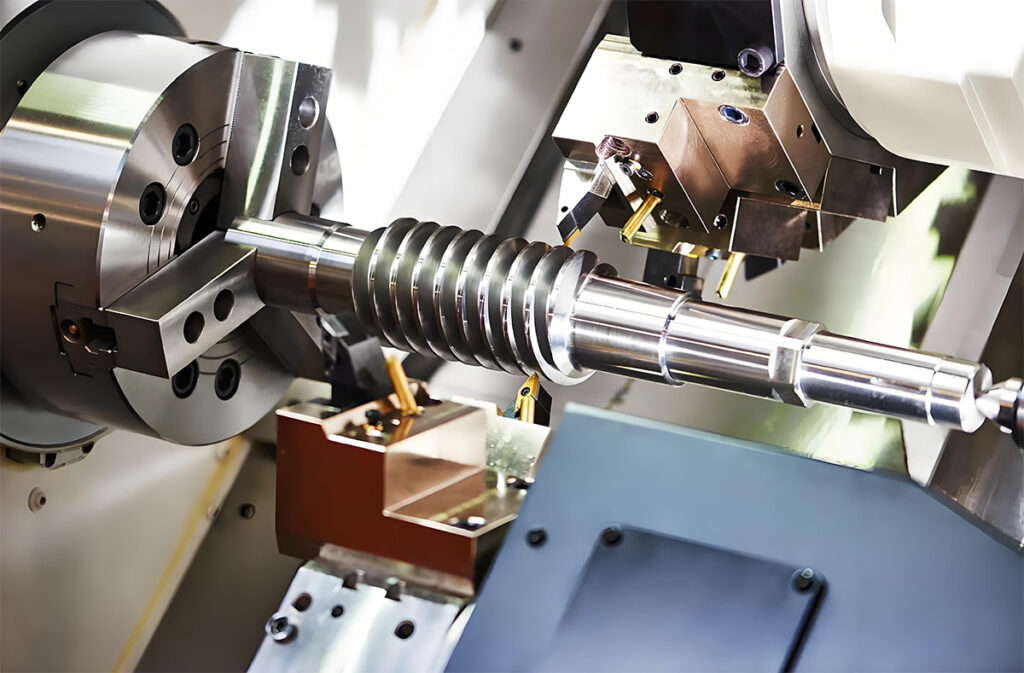

What is Swiss Screw Machining Parts

In the world of precision manufacturing, few methods can match the accuracy and versatility of Swiss screw machining parts. Whether it’s a tiny bone screw for orthopedic surgery or a connector in a spacecraft, these parts are the unsung heroes behind many of the technologies we rely on daily. Swiss screw machining was originally developed […]

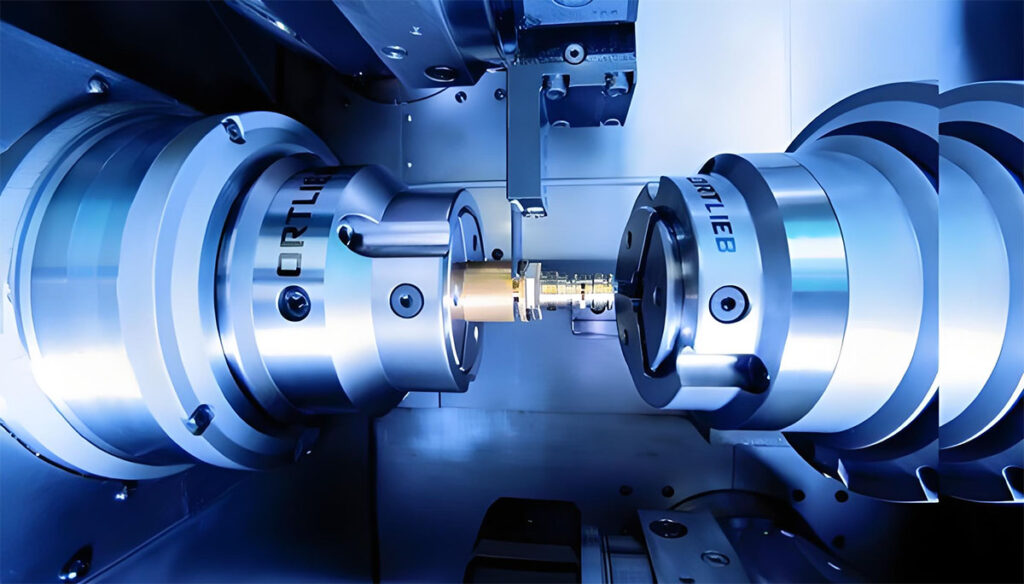

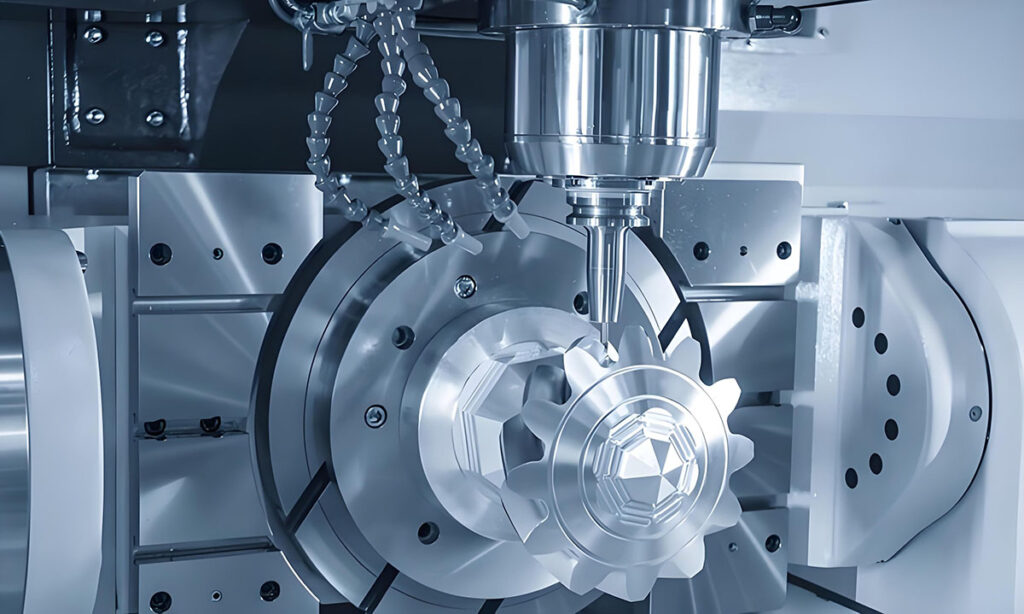

Multi-Axis CNC Turning Parts for Modern Manufacturing

In today’s fast-changing industrial world, precision is everything. Whether it’s a small medical screw or a complex aerospace fitting, every part must meet tight specifications. That’s where Multi-axis CNC Turning Parts come in. These components are made using advanced machines that rotate and cut from different angles, all in one go. That means fewer errors, […]

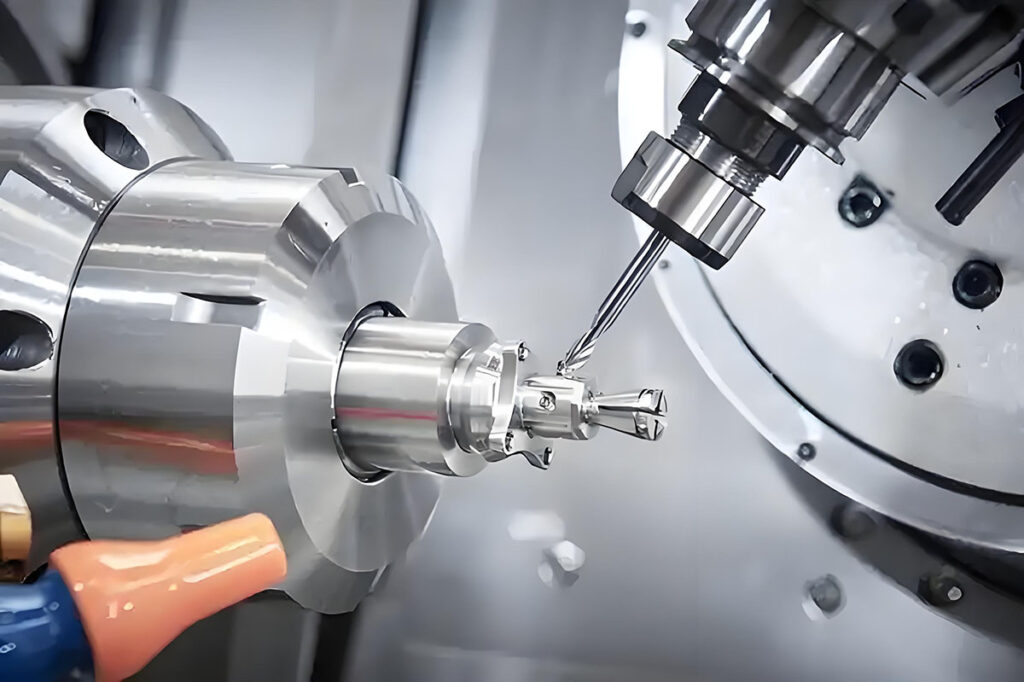

Top 10 Benefits of 5-Axis CNC Precision Machining Services for Modern Manufacturing

Discover how 5-axis CNC precision machining services revolutionize complex part production with unmatched speed, accuracy, and versatility. Today’s manufacturers are under pressure to deliver precision, speed, and efficiency like never before. From aerospace turbines to medical implants, the demand for complex, high-tolerance parts is growing fast. That’s where 5-axis CNC precision machining services step in […]

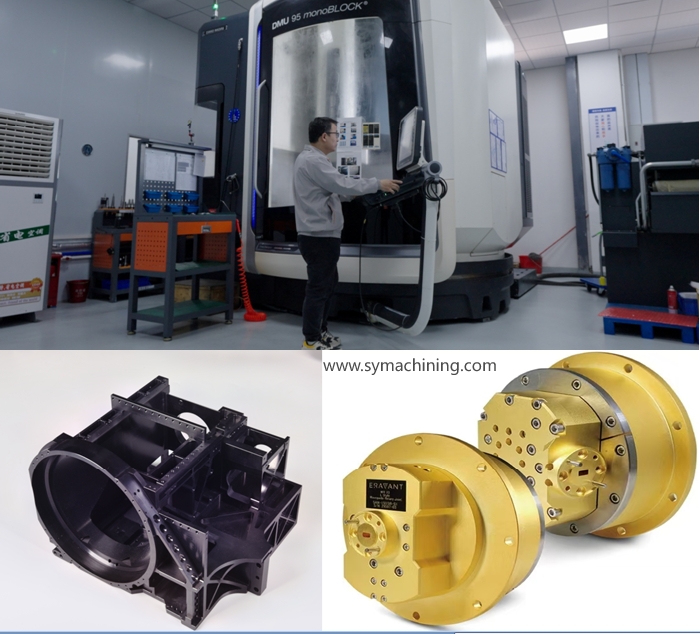

11 Must-Know Insights When Choosing a Precision Machined Components Supplier

Looking for a reliable precision machined components supplier? Discover essential insights on quality, materials, certifications, and cost-effective solutions for every industry. Introduction to Precision Machined Components When it comes to building high-quality products, choosing the right precision machined components supplier is key. These suppliers provide parts that are used in industries like aerospace, automotive, medical, […]

ISO 13485 Medical Machining: The Gold Standard for OEM Partnerships

In today’s highly regulated healthcare sector, ISO 13485 medical device machining stands as the gold standard for manufacturing safety-critical components. Whether you’re producing orthopedic implants, surgical tools, or diagnostic components, adhering to ISO 13485 ensures that your machining processes meet stringent quality and safety criteria. This global standard governs everything from documentation and traceability to […]

Advanced Aerospace Machining Services in China

Discover top-tier Aerospace Machining Services in China, comparing them with Southern California’s capabilities and advantages. In this comprehensive guide, we’ll explore why global aerospace manufacturers are turning eastward, how Chinese firms compare to their American counterparts, and what makes China such a strategic choice for sourcing precision components for aircraft, satellites, and space exploration vehicles. […]

Why Aerospace-grade Machined Components Are Critical to Modern Flight

Explore why Aerospace-grade machined components are vital in aviation and space industries. Learn about their materials, precision, and applications. Introduction to Aerospace-grade Machined Components Aerospace components are not your everyday metal parts. They’re built for extremes—extreme altitudes, speeds, temperatures, and expectations. These parts have to be incredibly light but also super strong. Even the smallest […]

What is Custom Precision Machining

Discover why custom precision machining are essential for accurate, reliable, and high-performance manufacturing. Learn how to choose materials, reduce costs, and work with the right CNC machining partner. Introduction to custom precision machining Custom Precision Machining is a specialized manufacturing process that involves creating highly accurate, complex, and custom-designed parts or components to meet exact specifications. […]