Learn smart strategies for designing precision Turning Parts to improve accuracy, reduce machining time, and lower production costs efficiently.

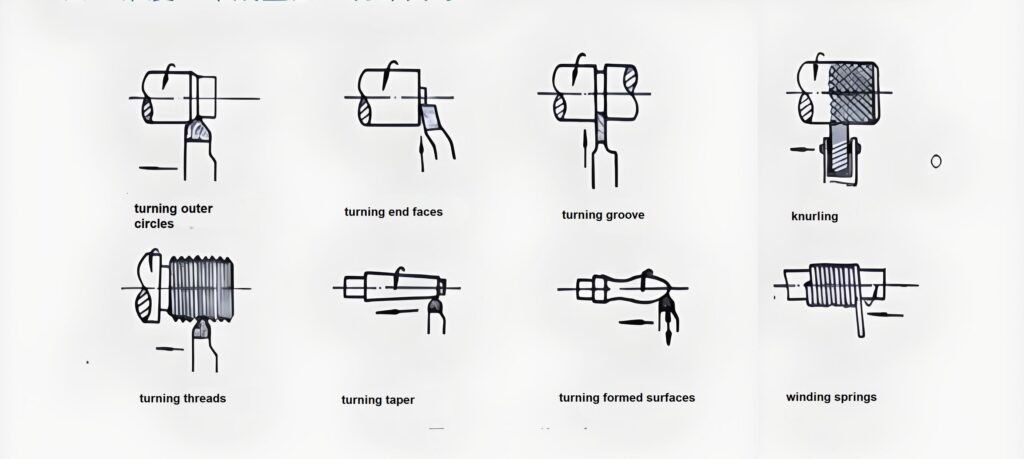

Precision Turning Services is mainly aimed at processing rotary bodies. On a lathe, the following processes can be carried out: turning outer circles, turning end faces, turning taper, knurling, turning formed surfaces, and winding springs, etc.

Precision Turning Parts

Precision Turning Parts are components created using a Lathe machine that uses rotary cutting to shape material into precise dimensions. These parts are commonly round or cylindrical, and they’re made by securing the workpiece on a chuck and rotating it while cutting tools remove excess material.

Some examples of turned parts include:

- Shafts and rods

- Sleeves and bushings

- Connectors and couplings

- Pins and bolts

- Custom pipe fittings

Turning services can be broadly categorized into two main types: Manual Lathe Machining and CNC Lathe Machining

Manual Lathe Machining

Operated manually by skilled machinists, conventional lathes rely on handwheels, levers, and mechanical adjustments to control cutting tools.

- Key Features:

- Flexibility: Ideal for low-volume production, prototyping, or custom one-off parts.

- Operator-Dependent: Accuracy depends on the machinist’s expertise.

- Cost-Effective: Lower initial setup costs for small batches.

- Limitations: Slower production rates and less precision compared to CNC for complex geometries.

- Common Applications: Simple shafts, bushings, and repairs.

CNC Lathe Machining

- Overview: Computer Numerical Control (CNC) lathes automate the turning process using programmed instructions (G-code) for high precision and repeatability.

- Key Features:

- High Precision: Tolerances within microns, suitable for intricate designs (e.g., threads, tapers).

- Efficiency: Faster production, especially for high-volume orders.

- Multi-Axis Capability: Advanced CNC lathes (e.g., Swiss-type, live-tooling) perform milling, drilling, and threading in one setup.

- Consistency: Minimal human error, ideal for mass production.

- Common Applications: Aerospace components, medical devices, automotive parts, and complex industrial fittings.

Both methods have unique advantages—Manual turning for flexibility and CNC turning for precision and scalability. The choice depends on project requirements, budget, and production volume.

Key Points of Precision Turned Parts Design

When designing precision turning parts, several important points should be noted:

- Material selection: Choose appropriate materials based on the part’s function, strength requirements, and machinability.

- Geometric complexity: Consider the limitations of turning operations and design parts that can be efficiently produced on a lathe.

- Tolerances: Specify realistic tolerances that balance functional requirements with manufacturing capabilities.

- Surface finish: Define the required surface finish for each feature, considering both functional and aesthetic aspects.

- Tool accessibility: Ensure that all features can be reached by cutting tools without interference.

- Fixturing and workholding: Design parts with considerations for how they will be held during machining.

- Minimize setup changes: Design parts to minimize the number of setups required, if possible.

- Standard sizes: Use standard stock sizes and tooling when possible to reduce costs.

- Avoid sharp internal corners: Include fillets or radii to improve machinability and reduce stress concentrations.

- Consider post-processing: Account for any secondary operations or treatments that may be required after turning.

By keeping these points in mind, designers can create precision turning parts that are both functional and efficient to manufacture.

Raw Material Selection Considerations

When selecting raw materials for precision turning parts, consider the following factors:

- Cost of materials: Balance material costs with performance requirements to optimize overall production expenses.

- Machinability : Choose materials that are conducive to efficient manufacturing and processing, reducing tool wear and production time.

- Material shape: Select bar or pipe materials with dimensions and specifications similar to existing market sizes to minimize processing and reduce costs.

By carefully considering these aspects of raw material selection, manufacturers can significantly improve the efficiency and cost-effectiveness of precision turning operations.

Dimensional Accuracy and Design Considerations

When designing precision turning parts, consider the following points for dimensional accuracy and manufacturability:

- For long shafts or deep holes, use sectional tolerance to ensure accuracy in critical areas.

- Avoid deep hole processing when possible. Instead, design with two-end processing holes to reduce the need for blind holes.

- Design hole bottoms with inner radii, leaving room for the tool to avoid creating voids or sharp corners.

These design considerations can significantly improve the manufacturability and quality of precision turned parts, especially for complex geometries or parts with critical dimensional requirements.

Limitations and Non-Turnable Features

While precision turning is a powerful manufacturing method, it does have its limits. Not every part can or should be made using turning. Knowing these restrictions can save time, money, and frustration.

What Turning Can’t Do

Precision turning is best for parts with a round or cylindrical shape. If your part has sharp angles, deep cavities, or complex contours that aren’t symmetrical around a central axis, turning service might not be the best method.

Here are some features that are difficult or impossible to create using only turning:

- Square or flat surfaces on all sides

- Intricate internal cavities

- Asymmetrical or multi-axis geometries

- Deep holes at odd angles

- Under cuts that require milling

These designs may require additional operations like CNC milling or even 5-axis machining.

Thread Design and Additional Considerations

When designing threads for turning parts, keep the following points in mind:

- Use standard thread profiles: Whenever possible, utilize standard thread designs (e.g., metric, UNC, UNF) to ensure compatibility and ease of manufacturing.

- Consider thread depth: Design threads with appropriate depth to balance strength and manufacturability.

- Include thread relief: Incorporate thread relief grooves to allow for proper tool clearance and complete thread formation.

Additional design considerations:

- Retracting slots: When designing retracting slots, ensure they are wide enough for tool clearance and deep enough to accommodate the retraction movement.

- Hole chamfers: Include chamfers at the entrance of holes to aid in part assembly and reduce the risk of cross-threading.

By incorporating these design elements, you can improve the functionality and manufacturability of turned parts, especially those requiring threaded features or precise fits.

Typical processing that can be accomplished by a horizontal lathe

Design Tips for Precision Turned Parts

Getting the best performance from precision turning starts at the design phase. A well-thought-out design will reduce machining time, improve quality, and lower production costs.

- Keep Designs Turning-Friendly: Stick to shapes that rotate easily around a central axis. This makes programming and setup easier and reduces machine wear.

- Avoid Unnecessary Complexity: Simpler designs are cheaper to produce. Avoid sharp transitions or very small radii unless absolutely necessary. Smooth curves are easier and faster to cut.

- Use Standard Dimensions: Designing parts with standard hole sizes, thread types, and surface finishes helps keep costs down and speeds up production.

- Add Chamfers and Fillets: These small touches can improve part durability and make the piece easier to handle and assemble. They also help reduce stress points.

- Design for Tool Clearance: Make sure there’s enough space for the turning tool to move freely without crashing into the part or machine.

Following these design principles ensures your precision turning parts are made faster, more accurately, and at a lower cost.

Surface Appearance Requirements

When designing precision turning parts, consider the following surface appearance requirements:

- Deburring and chamfering: Specify requirements for edge finishing to improve part appearance and safety.

- Roughness requirements: precision turning can achieve surface roughness values between Ra0.8 and Ra3.2. Set the roughness value based on required surface accuracy, keeping in mind that higher precision increases manufacturing costs.

- Lettering: Consider laser lettering as a cost-effective alternative to engraving. For long axis parts, avoid placing lettering at both ends and consider the vertical space limitations of lettering machines. Prefer axial typesetting and avoid lettering around the outside diameter when possible.

- Long shaft design: For long shafts, consider adding top pinholes at both ends if it doesn’t affect appearance or functional requirements. This can facilitate easier turning operations.

By addressing these surface appearance requirements in the design phase, you can ensure that the final turned parts meet both functional and aesthetic standards while optimizing manufacturing processes.

Relevant article : Top 6 Must-Know Facts About CNC Turning Parts for Precision Engineering