Discover everything you need to know about custom high quality precision machined parts, from their creation to their applications in various industries.

Introduction: What Are Custom High Quality Precision Machined Parts?

Custom high quality precision machined parts are essential components used in a wide range of industries, from aerospace and automotive to medical devices and electronics. These parts are manufactured using specialized machines that ensure exacting tolerances and high precision. Unlike mass-produced parts, custom precision machined parts are tailored to fit specific applications, ensuring optimal performance and reliability.

At their core, these parts are crafted through the use of CNC machines, which are programmed to cut, shape, and refine materials with extreme accuracy. This level of precision is critical for industries where even the smallest defect can have serious consequences.

Custom high quality precision machined parts are not just about meeting specifications, they are about exceeding expectations. These parts are designed for durability, reliability, and the highest performance, all while adhering to strict quality standards. Whether you need a single prototype or a batch of components, custom machining ensures that the end product is perfect for your needs.

Why Choose Custom High Quality Precision Machined Parts?

Key Benefits of Custom Machining

There are several reasons why custom high-quality precision machined parts are a preferred choice for industries that demand excellence. Let’s explore some of the top benefits:

Precision and Accuracy: Custom machined parts are designed to meet exact specifications, ensuring they fit perfectly and operate efficiently. This precision is vital in sectors like aerospace, where safety is a top priority.

Durability: High-quality materials are used in the machining process, resulting in parts that are built to last. Whether it’s a metal part for a car engine or a plastic component for medical equipment, these parts are designed to withstand harsh conditions.

Tailored Fit: Custom machining allows parts to be tailored to specific applications, meaning they will function more efficiently and effectively than off-the-shelf components.

Increased Performance: With custom parts, the overall performance of the machinery or device is optimized. These parts are made to meet exact design parameters, ensuring optimal performance.

By choosing custom high-quality precision machined parts, industries can ensure that their products are reliable, efficient, and perform at the highest standards.

How Custom High-Quality Precision Machined Parts Are Made

The CNC Machining Process

The process of making custom high-quality precision machined parts involves using advanced CNC machinery. Here’s how the process works:

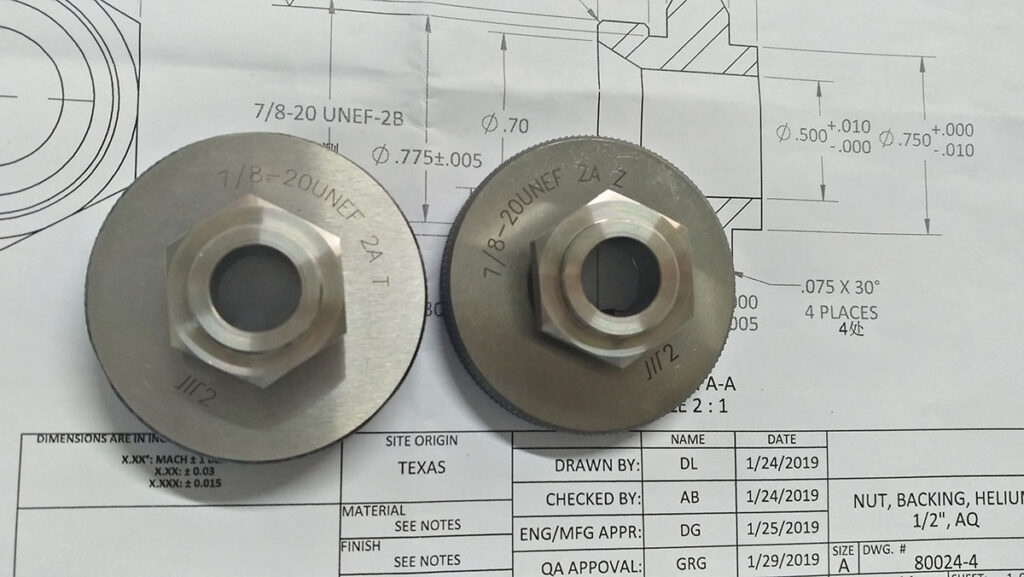

1. Design and Blueprinting: The first step in the CNC machining process is creating a detailed design or blueprint for the part. This design specifies the dimensions, material, and features of the part, ensuring it meets the required standards.

2. Material Selection: Based on the design, the appropriate material is selected. Common materials for precision machining include metals like stainless steel, aluminum, and titanium, as well as plastics and composites.

3. Machining: The CNC machine uses tools such as drills, mills, lathes, and grinders to cut and shape the material according to the design specifications. This step requires high precision to ensure the part meets exact dimensions.

4. Finishing: Once the part is shaped, it undergoes finishing processes, such as polishing, coating, or heat treatment, to enhance its appearance and performance.

5. Inspection: The final step involves inspecting the part for any defects or inaccuracies. Quality control checks ensure that the part meets the necessary specifications before it is delivered.

Materials Used in Custom High Quality Precision Machined Parts

Common Materials and Their Applications

The choice of material plays a crucial role in the quality and performance of precision machined parts. Some common materials used in custom machining include:

Stainless Steel: Known for its corrosion resistance and strength, stainless steel is commonly used for parts that need to withstand extreme conditions, such as in the medical and automotive industries.

Aluminum: Lightweight yet strong, aluminum is ideal for aerospace and automotive parts. Its ability to be easily machined makes it a popular choice.

Titanium: Strong and lightweight, titanium is often used in aerospace and military applications due to its excellent strength to weight ratio and resistance to corrosion.

Plastics and Composites: In applications where weight and flexibility are important, plastics such as nylon or polycarbonate, and composite materials are used to create durable yet lightweight parts.

Each material is selected based on the requirements of the specific application, including factors like strength, durability, and resistance to environmental factors like heat, chemicals, and corrosion.

Applications of High Quality Precision Machined Parts

Industries That Rely on Precision Machined Parts

Custom high-quality precision machined parts are used across a wide range of industries. Here are some examples:

Aerospace: Precision machined parts are used in the construction of aircraft, rockets, and satellites. These parts must meet strict safety and performance standards.

Automotive: From engine components to braking systems, precision machined parts are essential for ensuring the safety, performance, and reliability of vehicles.

Medical Devices: Medical devices such as surgical instruments, implants, and diagnostic equipment require high precision to ensure accuracy and patient safety.

Electronics: Components like connectors, housings, and microchips require precision machining to ensure proper functioning in electronic devices.

These industries demand precision, reliability, and durability—qualities that custom machined parts can provide.

Selecting the Right Manufacturer for High-Quality Precision Machined Parts

Factors to Consider in Choosing a Manufacturer

Choosing the right manufacturer for your custom high-quality precision machined parts is crucial. Here are some factors to consider:

Experience: Look for a manufacturer with a proven track record of producing high-quality precision parts for your industry.

Capabilities: Ensure the manufacturer has the right equipment and expertise to produce the specific parts you need.

Quality Control: A good manufacturer will have robust quality control processes in place to ensure your parts meet exact specifications.

Lead Times: Depending on your project, you may need quick turnaround times. Choose a manufacturer that can meet your deadlines.

Cost: While cost should not be the only factor, it’s important to find a manufacturer that offers competitive pricing without compromising quality.

Quality Control in Custom High-Quality Precision Machined Parts

Ensuring Accuracy and Durability

Quality control is essential in the production of custom high-quality precision machined parts. Some key aspects of quality control include:

Dimensional Inspections: Parts are carefully measured to ensure they meet the specified dimensions and tolerances.

Material Certification: The material used in manufacturing is tested to ensure it meets the required standards for strength, durability, and other properties.

Visual Inspections: Parts are visually inspected for defects such as cracks, burrs, or surface imperfections.

Functional Testing: Some parts undergo functional testing to ensure they perform as intended under real-world conditions.

Cost Factors for Custom High-Quality Precision Machined Parts

Understanding the Cost Structure

The cost of custom high-quality precision machined parts depends on several factors:

Material: Different materials have different costs, with metals like titanium being more expensive than aluminum or plastic.

Complexity: The more intricate the design, the more expensive the part will be to machine. Complex geometries and tight tolerances require more time and effort to produce.

Volume: The cost per part often decreases with larger order quantities, but custom machining is typically more expensive for small batch production.

Understanding these factors can help you plan your budget accordingly.

Common Challenges in Producing Custom High-Quality Precision Machined Parts

Addressing Potential Issues in Production

While custom precision machining offers many benefits, there are also challenges that manufacturers must address:

Material Challenges: Some materials are difficult to machine and may require special equipment or techniques.

Cost Overruns: The complexity of custom machining can sometimes lead to unexpected costs, especially if the design changes mid-production.

Quality Assurance: Maintaining high-quality standards throughout the production process is critical, and failure to do so can result in defective parts.

By identifying these challenges early on, you can work with your manufacturer to ensure a smooth production process.

The Future of Custom High-Quality Precision Machined Parts

Trends and Innovations in Precision Machining

The future of custom high-quality precision machined parts looks bright, with several exciting developments on the horizon:

Automation: Advances in automation and robotics are making the machining process faster and more efficient.

Additive Manufacturing: 3D printing is being integrated with traditional machining to create complex parts that were once impossible to produce.

Smart Manufacturing: The use of IoT (Internet of Things) devices and AI (artificial intelligence) is allowing for smarter, more efficient production processes.

These innovations promise to make precision machining even more cost-effective and reliable in the years to come.

Conclusion

Custom high-quality precision machined parts are crucial for industries that demand excellence. By understanding the machining process, selecting the right manufacturer, and ensuring high-quality standards, companies can create parts that perform at the highest level. As technology continues to advance, the future of precision machining looks even more promising, with innovations that will further improve the quality, cost, and efficiency of these essential components.