Learn everything about the cost of CNC machining per hour, what influences the price, tips to lower your costs, and what to expect when working with low-cost CNC machining services.

Introduction to CNC Machining Costs

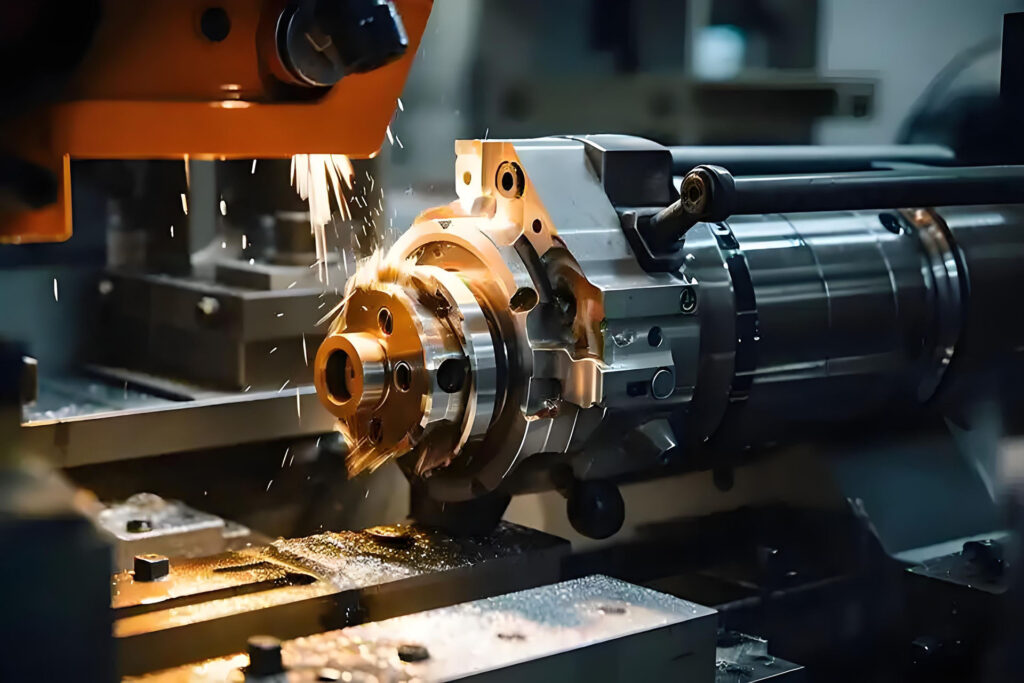

CNC machining has changed how we make parts. From tiny screws to airplane parts, CNC machining helps turn metal and plastic into precision products. But one common question always comes up: how much does CNC machining cost per hour?

Understanding this is key, whether you’re designing your first prototype or ordering 10,000 parts. While prices vary, there are solid reasons behind every number you see on a quote.

Let’s break down the details so you can make smart, budget-friendly choices for your next CNC job.

Understanding the Cost of CNC Machining Per Hour

Average Rates in Different Regions

The cost of CNC machining per hour varies widely based on where you are. In the United States, the hourly rate typically ranges from $75 to $200 depending on the shop’s capabilities. In Europe, rates might be similar or slightly higher. Asia, especially China and India, offers much lower-cost CNC machining, sometimes around $20 to $60 per hour.

Here’s a quick comparison table:

| Region | Hourly CNC Machining Cost (USD) |

| North America | $75 – $200 |

| Europe | $80 – $220 |

| China | $20 – $60 |

| India | $25 – $55 |

Choosing a shop isn’t just about price—it’s about the quality, delivery, and communication too.

How Machine Type Affects Cost?

Different CNC machines mean different pricing. A basic 3-axis machine costs less to run than a complex 5-axis CNC machine, which requires more programming, setup, and precision.

Here’s how machine type plays a role:

3-Axis Machines: More affordable, best for simple parts

4/5-Axis Machines: Higher hourly rates, but save time on complex parts

CNC Lathes: Great for round parts, mid-range in cost

If you’re curious about specific machine types, a custom CNC machining service provider can walk you through the best option for your design.

Factors That Affect CNC Machining Costs

Material Selection and Tooling Expenses

Materials are a big cost factor. Metals like titanium or copper are harder to cut and more expensive than aluminum or plastic. The more wear-and-tear on the cutting tools, the more replacements are needed—costs go up!

Common material pricing per kg (rough estimate):

| Material | Average Cost (USD/kg) |

| Aluminum | $3 – $5 |

| Stainless Steel | $4 – $6 |

| Titanium | $30 – $40 |

| Copper | $6 – $8 |

| Plastic | $1 – $3 |

If you’re looking for custom aluminum CNC machining, it remains a budget-friendly choice for many applications.

Machine Setup and Programming Time

Setup isn’t just flipping a switch. CNC operators need to program the part, install tools, and test everything before running production. Setup time may cost you $50 to $200, depending on complexity. For a simple part, it’s quick. For complex custom CNC turned parts, it could take hours.

Part Complexity and Quantity

Complex parts take more machine time, which increases hourly costs. Also, fewer quantities = higher cost per part. So, making 1 prototype is always more expensive per unit than making 1,000 parts.

Hourly Rates Based on Machine Type

3-Axis vs 5-Axis CNC Machine Costs

The type of machine you choose affects the cost of CNC machining per hour more than you might think. A standard 3-axis CNC machine is commonly used and offers affordability for many basic shapes. These machines typically cost $75 to $100 per hour, depending on location and capabilities.

However, for parts that need more complex cuts and angles, a 5-axis CNC machine is a better fit. These offer better accuracy and reduce the number of setups, which can save time—but their hourly rates can shoot up to $150 to $250 per hour.

| Machine Type | Hourly Rate (USD) | Best For |

| 3-Axis CNC | $75 – $100 | Simple cuts, 2D & basic 3D parts |

| 5-Axis CNC | $150 – $250 | Complex geometry, aerospace, molds |

While 5-axis machines are more expensive, they may still be cost-effective overall due to shorter run times and fewer setups.

CNC Lathe Machining Cost Per Hour

CNC lathes are specialized for round components, like shafts and bushings. The cnc lathe machining cost per hour typically falls between $60 and $120, depending on how modern the machine is, and whether it’s operated manually or automatically.

CNC lathes are more affordable when producing high-volume turned parts. So if you need custom CNC turning parts, lathes offer a budget-friendly option for mass production.

Hidden and Additional Costs to Consider

Fixturing, Quality Checks, and Post-Processing

The hourly machining rate isn’t the whole story. Some additional costs might not be obvious at first but can add up quickly:

Fixturing & Tooling: Custom fixtures hold the part during machining. These may cost $100–$500 upfront.

Quality Checks: Some shops include basic checks. Advanced inspections like CMM (Coordinate Measuring Machine) scans may cost extra.

Post-Processing: Parts may need deburring, surface finishing, or anodizing, each with additional charges.

All of these are essential, especially for custom precision parts where quality matters.

Shipping, Packaging, and Handling Charges

Once parts are ready, they must be safely packaged and shipped. These costs depend on your location and order size. Small prototype orders might ship for $50, but large metal components could run into hundreds due to weight and fragility.

Tip: Always ask if shipping is included in your quote to avoid surprises!

Ways to Reduce CNC Machining Costs

Design for Manufacturability (DFM)

One of the smartest ways to lower machining costs is using DFM principles. That means designing your part so it’s easier and faster to machine. Here’s how:

- Avoid deep pockets and tight internal corners.

2. Use standard hole sizes for drilling.

3. Keep tolerances only where needed.

Talk to your custom machining near me provider early. They can suggest simple changes that save hours—and dollars.

Batch Production vs. Prototyping

Making just one part? That’s always going to cost more per unit. Why? Setup time is fixed. Whether you make 1 or 100 parts, the machine needs the same setup.

Larger batches mean that setup costs are spread out. So even though total cost goes up, cost per part goes down.

| Quantity | Cost Per Part |

| 1 | $300 |

| 10 | $80 |

| 100 | $25 |

If you plan to order again, consider doing a small batch run instead of just a prototype.

How Low Cost CNC Machining Services Stay Competitive?

Outsourcing and Automation Advantages

Shops that offer low cost CNC machining services often leverage advanced strategies like:

1.Outsourcing repetitive work to reduce overhead

2.Using automation, like robotic arms, to keep machines running 24/7

3.Choosing affordable locations or countries for their facilities

If you’re on a budget, ask your supplier if they use any of these strategies. They can keep prices low without sacrificing quality.

How Small Shops Keep Prices Low

Smaller local CNC shops often have lower overhead and more flexible operations. They may not offer huge production runs, but for custom CNC machining near me, they’re often your best bet.

They can also give you more personal service and quicker response times—great when you need help fast!

Pricing Transparency in CNC Machining Quotes

What to Ask Your CNC Provider?

When requesting a quote, don’t be shy! Ask these questions to get a clearer picture:

- Is setup time included in the hourly rate?

- Are tooling or fixtures extra?

- Does the quote include post-processing?

- Are shipping and taxes added later?

Understanding Cost Breakdown in CNC Quotes

Good CNC providers will break down their quote into:

- Setup Cost

- Machining Time

- Material Cost

- Finishing

- Shipping

Some might add rush fees or engineering support fees, so read carefully.

This is key when comparing shops for your next custom CNC service. A lower price isn’t always a better deal.

FAQs About CNC Machining Costs

How much does CNC machining cost per hour on average?

— Typically, it ranges from $75–$150 per hour in North America. It can be lower in countries like China or India.

What’s the most affordable material to machine?

— Aluminum and plastics are cheaper to machine compared to titanium or stainless steel due to lower tool wear and shorter machining time.

Are there ways to reduce machining time?

— Yes. Simplifying part geometry, using larger tool radii, and minimizing setups will reduce the machining time.

Why do prototypes cost more per part?

— Because setup time is fixed. One prototype must absorb the full setup cost, making the per-part price high.

Is 5-axis machining always more expensive?

— Per hour, yes. But it can be faster overall, which might reduce your total project cost.

What is low cost machining and is it reliable?

— Low cost machining uses smart designs, automation, and efficient machines. When done by a trusted shop, it’s just as reliable

Conclusion

Understanding the cost of CNC machining per hour helps you make better choices for your manufacturing needs. Whether you’re looking for low cost machining, or investing in high-end custom precision machining, knowing what influences pricing puts you in control.

Want to get the most value? Focus on smart design, clear communication with your machinist, and transparency in quotes. Whether you choose a local shop or an overseas partner, these strategies ensure your project stays on time and within budget.

SYM Precision Machining offers cost-effective and high-quality CNC solutions tailored to your exact needs. Reach out to us today for a free quote!