Discover the essentials of CNC turning parts, from materials and design tips to pricing and applications. Learn how CNC turning fits your precision machining needs.

Introduction to CNC Turning Parts

CNC turning parts are the backbone of many of today’s industries, from aerospace to automotive, and everything in between. As technology has advanced, so has the accuracy and efficiency of CNC machines, especially in turning processes. This guide explores everything you need to know about CNC turning parts, including their production, costs, materials, and when to choose this method over others.

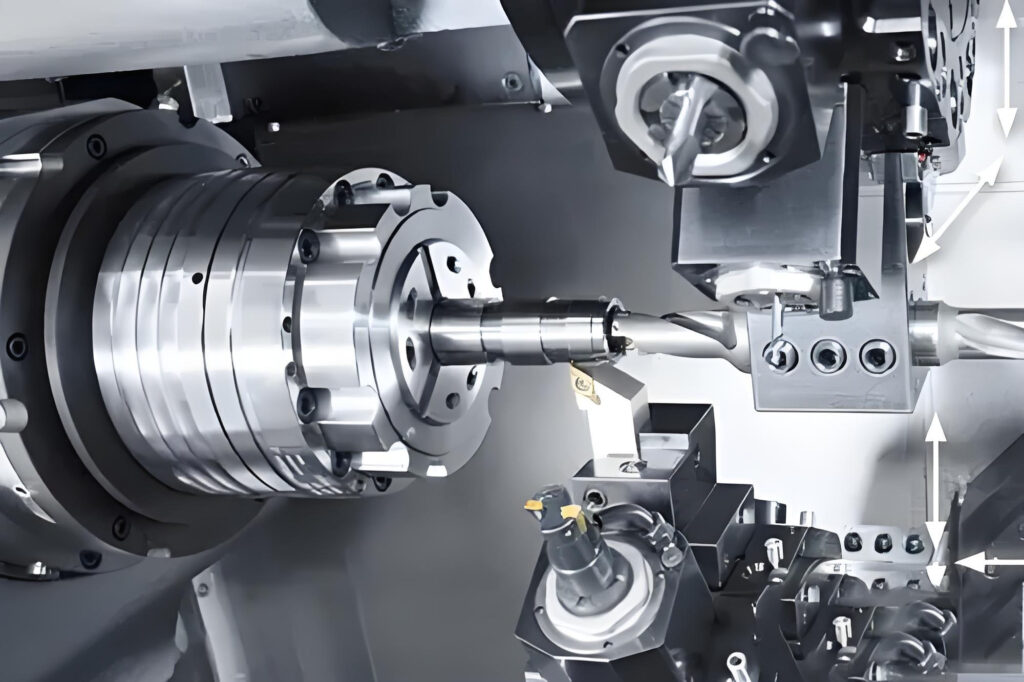

CNC turning involves a spinning piece of raw material that is cut by a stationary tool to create the desired shape. It’s a subtractive process that allows for precise shaping of cylindrical or round components, such as shafts, bushings, and pins. Whether you’re seeking precision CNC turning services, evaluating your supplier, or simply curious about what affects the cnc turning price, this article will answer your questions in detail.

Best Materials for CNC Turning

Choosing the right material is critical. It affects the cost, performance, and machining time of your project. Here are some commonly used materials for precision CNC turning parts:

| Material | Strength & Properties | Common Uses |

| Aluminum | Lightweight, corrosion-resistant, easy to machine | Aerospace, automotive, electronics |

| Stainless Steel | Strong, durable, corrosion-resistant | Medical devices, marine parts |

| Brass | Easy to machine, corrosion-resistant | Valves, plumbing, connectors |

| Titanium | High strength-to-weight ratio, corrosion-resistant | Aerospace, medical implants |

| Plastic (e.g., POM, PTFE) | Lightweight, chemical-resistant | Insulating components, consumer goods |

| Copper | Excellent conductivity, moderate strength | Electrical components, connectors |

| Carbon Steel | High strength, cost-effective, durable | Industrial machinery, tools |

The ideal material for your custom CNC metal cutting depends on your design requirements, strength needs, and industry regulations.

CNC Turning Fixture and Setup Essentials

A fixture is a tool that holds the workpiece in place while it’s being machined. In CNC turning, proper fixturing is critical to ensure part accuracy, repeatability, and safety.

Why Fixtures Matter

Without a secure fixture, the part might move during cutting. This causes errors, tool damage, or even machine failure. Fixtures help:

- Keep the part steady during high-speed rotation

- Reduce vibration and noise

- Improve surface finish

- Increase machining speed and efficiency

Common Fixtures in CNC Turning

- Chucks: These hold round parts tightly in place. Three-jaw chucks are the most common.

- Collets: Used for holding smaller or delicate parts. They provide even clamping pressure.

- Faceplates: Ideal for irregularly shaped parts that can’t be held by a chuck.

- Tailstocks: Offer additional support for long parts to prevent bending or wobbling.

A well-set-up fixture reduces downtime and improves part consistency—especially for high-volume cnc turning part manufacturing runs.

What Affects CNC Turning Price

CNC turning is a widely used machining process for creating cylindrical parts, but the cost can vary significantly depending on several factors. Understanding these factors can help businesses budget effectively and optimize production costs.

Material Type

The raw material used greatly impacts the price. Harder metals like stainless steel or titanium require more time and specialized tools, increasing costs compared to softer materials like aluminum or brass.

Part Complexity

Simple cylindrical parts are cheaper to produce, while intricate designs with tight tolerances, deep grooves, or threading demand advanced tooling and longer machining time, raising the price.

Batch Size

Larger production runs reduce the per-unit cost due to economies of scale. Small batches or one-off prototypes often have higher setup costs.

Machine Time

Longer machining times increase labor and operational expenses. Complex geometries or high-precision requirements extend cycle times, affecting the final price.

Surface Finish & Tolerances

Tighter tolerances and superior surface finishes (e.g., polishing or anodizing) require additional steps, increasing costs.

Tooling & Setup

Custom fixtures or specialized cutting tools add to expenses, especially for unique part designs.

By considering these factors, manufacturers and buyers can better estimate CNC turning costs and make informed decisions for their projects.

How CNC Turning Differs from CNC Milling?

It’s easy to confuse CNC turning with CNC milling, but they’re quite different processes.

| Feature | CNC Turning | CNC Milling |

| Workpiece Movement | Rotates | Stays still |

| Tool Movement | Stationary or moves linearly | Moves around the workpiece |

| Best For | Cylindrical parts | Flat, irregular, or complex shapes |

| Material Removal | Rotary cutting | Rotary and multi-axis cutting |

| Typical Products | Shafts, bushings, pins, screws | Brackets, housings, gears |

If you’re working with round parts like pins, rods, or axles, vertical CNC turning or horizontal turning will likely be more efficient. For more complex parts with multiple features, CNC milling may be required instead.

Often, manufacturers use a mix of both to get the job done right—especially for precision CNC turning services that require perfect finishing.

When to Use Another Process?

If your project includes parts with varied angles, holes from multiple directions, or surface patterns, custom CNC milling services might be better suited. Milling offers more flexibility in part geometry.

A good rule of thumb: if the part is mostly round or symmetrical around a central axis, CNC turning is a great option. If it’s more complex or flat, consider combining processes for better results.

Applications of CNC Turning Parts

CNC turning plays a vital role in many industries because it’s reliable, fast, and perfect for making strong, precise parts. These turned parts are everywhere—even in places we don’t notice.

Why CNC Turning Is Chosen?

- Consistency: You get the same result every time—even in high volumes.

- Speed: Turning machines work fast, especially with automated feeding.

- Precision: Perfect for tight tolerances and smooth finishes.

- Customization: Easy to adjust the program for different dimensions or materials.

That’s why so many companies turn to custom CNC turning parts when they need quality, speed, and exact specifications.

Common Types of CNC Turning Parts

These parts are the foundation of many high-performance machines and products. They are made by rotating a metal rod and cutting away material using precision tools.

- Bushings: Used in automotive, robotics, and aerospace for reducing friction.

- Shafts: Critical in engines, motors, and gearboxes.

- Collars and Rings: Often used in electronics and mechanical systems.

- Threaded Parts: Nuts, bolts, and custom fasteners made to fit tight specifications.

- Pins and Spindles: Small but important components for guiding or locking other parts.

Frequently Asked Questions about CNC Turning Parts

What are CNC turned parts used for?

CNC turning parts are used in many industries like automotive, aerospace, medical, and electronics. They include shafts, bushings, pins, threaded rods, and other round or cylindrical components that require high accuracy.

How much does CNC turning cost per hour?

The cost of CNC machining per hour varies depending on the machine type, part complexity, and location. On average, it ranges from $40 to $120 per hour. More advanced machines or tight tolerance work may increase the price.

What is the difference between CNC milling and CNC turning?

CNC milling uses rotating tools to cut material from a fixed block, while CNC turning rotates the material and uses stationary tools to remove material. Turning is ideal for round shapes, while milling handles more complex, non-cylindrical forms.

Can I get custom CNC machine turning parts in small quantities?

Yes! Many cnc turning manufacturers offer low-volume or even one-off production. Look for custom CNC machining services or custom machining near me that specialize in prototypes or small batch runs.

Which materials are best for CNC turning?

Common choices include aluminum, steel, brass, titanium, and various plastics. The best material depends on your part’s strength, weight, and corrosion-resistance needs.

Do CNC turning shops offer finishing services?

Many shops do! You can request finishes like anodizing, polishing, powder coating, or plating. These add protection and make the part look more professional.

Conclusion

CNC turning is a powerful and flexible process for creating precision parts. Whether you’re designing something simple or highly complex, understanding how CNC turning works—and what affects pricing—can help you make better decisions.

When you need reliable, high-quality parts, working with an experienced CNC turning specialist is key. They’ll help you choose the right material, get tight tolerances, and deliver on time. The good news? You don’t have to go far—great custom CNC machining services are available online and often nearby.

By knowing what to look for in a CNC turning shop—equipment, service, quality, and communication—you can save time and money while getting great results. Whether you’re in need of custom titanium machining, cnc turning plastic, or precision CNC turning parts, there’s a solution that fits your needs and budget.

So next time you’re thinking about custom parts, remember the benefits of CNC turning—it’s fast, precise, and made for professionals like you.

Looking for top-quality CNC turning parts?

SYM Precision Machining offers custom solutions with no minimum order—delivering precision, speed, and reliability every time.

Relevant article: Expert Tips for Designing precision Turning Parts