Scoprite perché le lavorazioni meccaniche di precisione personalizzate sono essenziali per una produzione accurata, affidabile e ad alte prestazioni. Imparate a scegliere i materiali, a ridurre i costi e a lavorare con il partner giusto per la lavorazione CNC.

Introduzione alla lavorazione di precisione personalizzata

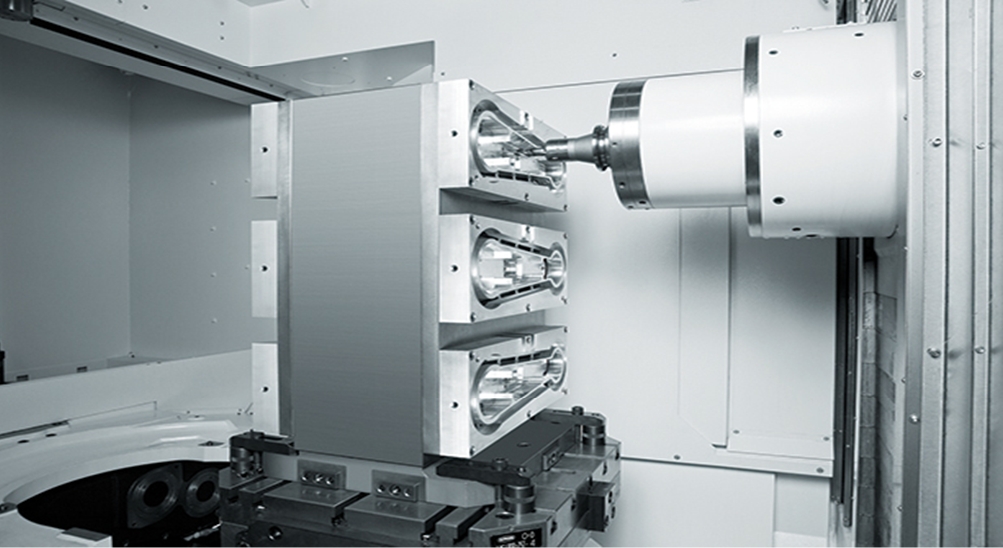

Lavorazione di precisione personalizzata è un processo di produzione specializzato che prevede la creazione di parti o componenti altamente precisi, complessi e progettati su misura per soddisfare le specifiche esatte. Utilizza tecniche di lavorazione avanzate, tolleranze ristrette e materiali di alta qualità per produrre pezzi di eccezionale precisione e ripetibilità.

I pezzi lavorati di precisione su misura sono gli elementi costitutivi della produzione moderna. Quando si tratta di settori come quello aerospaziale, automobilistico, dei dispositivi medici o della robotica, la precisione è tutto.

Perché scegliere la personalizzazione? Perché non esistono due progetti esattamente uguali. Servono materiali, forme e tolleranze specifiche che i pezzi standard non possono offrire. Ed è qui che entrano in gioco i servizi di lavorazione CNC personalizzati.

In questa guida vi illustreremo tutto ciò che dovete sapere, dalla scelta dei materiali giusti alla comprensione dei fattori di costo, fino alla ricerca di un partner affidabile per la lavorazione. Vi mostreremo anche perché SYM Precision Machining è un nome di fiducia quando si tratta di pezzi di precisione personalizzati per piccole serie o per produzioni in grandi volumi.

Perché la precisione è importante?

Pensate a un lavoro di taglio del metallo CNC personalizzato per un motore aerospaziale. Se il pezzo è sbagliato anche solo di una frazione, potrebbe causare un guasto al sistema. Oppure considerate le parti tornite CNC personalizzate di un impianto medico. Questi pezzi devono essere biocompatibili e perfettamente adattati all'anatomia del paziente.

La precisione non riguarda solo l'aspetto estetico, ma anche la sicurezza, la funzionalità e le prestazioni.

Tipi di lavorazione di precisione personalizzata

- Lavorazione CNC personalizzata: Utilizza strumenti automatizzati per rimuovere il materiale da un pezzo.

- Servizio di fresatura CNC personalizzato: Una fresa rotante rimuove il materiale, ideale per le superfici piane o gli elementi angolati.

- Parti di tornitura CNC personalizzate: Utilizzato per realizzare componenti cilindrici con simmetria rotazionale.

- Taglio CNC personalizzato: Gli utensili ad alta velocità tagliano con precisione metalli come l'alluminio e il titanio.

Ogni tecnica risponde a un'esigenza diversa e spesso ne vengono combinate diverse per ottenere una soluzione completa.

Materiali utilizzati nella lavorazione di precisione personalizzata

La scelta del materiale giusto è il primo passo, e uno dei più importanti, per creare un pezzo di precisione di successo. Le prestazioni, il costo, la lavorabilità e persino la durata di un pezzo dipendono dalla scelta del materiale.

Materiali popolari per parti di precisione personalizzate

| Materiale | Caratteristiche | Usi comuni |

| Alluminio | Leggero, resistente alla corrosione, facile da lavorare | Droni, elettronica, automotive |

| Titanio | Elevato rapporto resistenza/peso, biocompatibile | Aerospaziale, impianti medici |

| Acciaio inox | Robusto e resistente alla corrosione | Settore navale, agroalimentare, automobilistico |

| Plastica (ad esempio, PEEK, Delrin) | Leggero, resistente agli agenti chimici | Medicale, elettronica, prototipazione |

Cose da considerare nella scelta dei materiali

- Requisiti per l'applicazione: Il pezzo deve resistere al calore o alla corrosione?

- Bilancio: L'alluminio è più economico del titanio, ma potrebbe non soddisfare le esigenze di resistenza.

- Tolleranza: Alcuni materiali sono più facili da lavorare con tolleranze strette.

Con SYM servizi di lavorazione di precisione personalizzati, è possibile ottenere la consulenza di un esperto sulla scelta del materiale in base alla propria applicazione specifica.

Considerazioni sulla progettazione di parti lavorate

Potete avere la migliore officina meccanica del mondo, ma se il vostro progetto non è ottimizzato per la lavorazione, potrebbe costare più tempo e denaro del necessario. Ecco perché la progettazione per la producibilità (DFM) è così importante per la produzione di prodotti. lavorazione di precisione personalizzata.

Suggerimenti per ottimizzare il design

- Ridurre al minimo gli angoli vivi: Utilizzare filetti e raggi per ridurre l'usura degli utensili e accelerare la lavorazione.

- Semplificare la geometria: Più semplice è il progetto, più bassi sono i costi e i tempi di realizzazione.

- Richiamare solo le caratteristiche critiche: Non sovraspecificare le tolleranze se non è necessario.

Perché i modelli CAD sono importanti?

I modelli CAD dettagliati consentono alle macchine CNC di seguire il progetto con estrema precisione. Assicuratevi che i vostri file siano aggiornati e contengano informazioni complete: questo vale soprattutto per i pezzi di fresatura e tornitura CNC personalizzati.

Avete bisogno di aiuto per perfezionare il vostro progetto? SYM offre parti di lavorazione CNC personalizzate e lavora a stretto contatto con gli ingegneri per individuare i problemi prima dell'avvio della produzione.

Come funzionano i servizi di lavorazione CNC personalizzati?

I servizi di lavorazione CNC personalizzati sono la spina dorsale della produzione di precisione. Che si tratti di creare un singolo prototipo o di passare alla produzione completa, la comprensione del processo vi aiuta a prendere decisioni più intelligenti.

Flusso di lavoro della lavorazione CNC passo dopo passo

- Presentazione del progetto

Si inizia inviando un disegno 2D o un file CAD 3D al fornitore della lavorazione. - Selezione del materiale

Il negozio esamina le vostre specifiche e vi aiuta a scegliere un materiale adatto, come l'alluminio, il titanio o l'acciaio inossidabile. - Programmazione CAM

Il software CAM (Computer-Aided Manufacturing) traduce il modello CAD in percorsi utensile. - Impostazione della macchina

La macchina CNC viene caricata con utensili e materiale, quindi calibrata per un taglio preciso. - Lavorazione e ispezione

Il pezzo viene tagliato secondo le specifiche, quindi ispezionato per il controllo qualità utilizzando micrometri, CMM o scanner laser. - Finitura e consegna

Processi opzionali come anodizzazione, verniciatura a polvere o lucidatura vengono applicati prima della spedizione del pezzo.

Diversi tipi di servizi

- Servizio di fresatura CNC personalizzato: Ideale per superfici piane o sagomate.

- Parti di tornitura CNC personalizzate: Ottimo per le forme cilindriche.

- Taglio metalli CNC personalizzato: Taglio preciso di metalli come acciaio inossidabile, titanio o rame.

Servizio CNC personalizzato per la prototipazione: Tempi rapidi per la convalida dei progetti.

A SYM Lavorazione di precisioneTutti questi servizi sono sotto lo stesso tetto, dai prototipi in tempi rapidi alla produzione su larga scala.

Capire i costi della lavorazione CNC personalizzata

Conoscere i fattori che concorrono alla determinazione del prezzo di lavorazione CNC personalizzata può aiutarvi a fare un bilancio migliore e a evitare sorprese.

Fattori che influenzano i costi della lavorazione CNC

| Fattore | Descrizione |

| Tipo di materiale | Il titanio è più costoso dell'alluminio e della plastica. |

| Parte Complessa | I disegni più complessi richiedono più tempo e utensili. |

| Requisiti di tolleranza | Tolleranze più strette significano una lavorazione più lenta e un maggior numero di ispezioni. |

| Finitura | I rivestimenti o i trattamenti aumentano i costi. |

| Volume | Gli ordini più grandi hanno un prezzo migliore per unità. |

Come ridurre i costi di lavorazione?

- Semplificare il design.

- Evitare tolleranze strettissime, a meno che non sia necessario.

- Scegliete materiali convenienti.

- Lottizzazione di pezzi simili per ottenere sconti sui volumi.

Avete bisogno di un preventivo? SYM offre servizi di lavorazione CNC personalizzati con prezzi trasparenti e senza minimi d'ordine.

Vantaggi della scelta del giusto partner di lavorazione personalizzata

Quando si tratta di lavorazione di precisione personalizzataLa scelta di un partner può rendere il vostro progetto più o meno importante. Ecco perché è importante.

- Qualità costante

L'officina giusta utilizza strumenti di ispezione come le CMM per garantire che ogni pezzo sia conforme alle vostre specifiche. - Consegna puntuale

I ritardi costano. Le officine esperte come SYM rispettano i programmi. - Supporto alla progettazione

Un buon partner aiuta a perfezionare il progetto per ottenere costi inferiori e prestazioni migliori. - Dimensioni d'ordine flessibili

Che abbiate bisogno di 1 pezzo o di 10.000, sono pronti ad aiutarvi. - Approvvigionamento di materiali

Possono approvvigionarsi di materiali di alta qualità, come l'alluminio aerospaziale o il titanio per uso medico.

Noi di SYM siamo orgogliosi di essere un fornitore affidabile ed esperto di parti lavorate di precisione personalizzate. Da lavorazione del titanio personalizzata a servizi personalizzati di alluminio CNCAbbiamo visto tutto e lavorato meglio.

Applicazioni dei componenti di precisione personalizzati in tutti i settori

I componenti lavorati su misura sono utilizzati ovunque, dalle automobili agli strumenti chirurgici. Vediamo la suddivisione per settore.

| Industria | Applicazione | Materiale comunemente utilizzato |

| Aerospaziale | Parti del motore, componenti strutturali | Titanio, alluminio |

| Medico | Impianti, strumenti chirurgici | Acciaio inox, PEEK |

| Automotive | Ingranaggi, carter motore | Alluminio, acciaio |

| Robotica | Giunti e staffe personalizzate | Alluminio, titanio |

| Elettronica | Dissipatori di calore, involucri | Rame, plastica |

Con il giusto servizio CNC personalizzatoè possibile creare componenti su misura per qualsiasi applicazione, migliorando l'adattamento, la durata e le prestazioni.

Perché scegliere SYM per la lavorazione di precisione personalizzata?

Quando si tratta di lavorazione personalizzata vicino a meSYM Precision Machining si distingue. Ecco cosa ci rende diversi:

I nostri punti di forza

- Team esperto: Decenni di conoscenze pratiche in diversi settori.

- Nessun ordine minimo: Da 1 pezzo a serie complete.

- Inventario dei materiali: Magazzino completo di alluminio, titanio e acciaio inox.

- Garanzia di qualità: Ogni pezzo viene sottoposto a controlli dettagliati prima della consegna.

- Tempi rapidi: Ci muoviamo velocemente senza tagliare gli angoli.

SYM è più di una semplice officina meccanica. Siamo il vostro partner di produzione: vi aiutiamo a progettare, sviluppare e consegnare pezzi personalizzati che funzionano perfettamente fin dall'inizio.

FAQ

A cosa servono i pezzi lavorati di precisione su misura?

Vengono utilizzati in settori in cui precisione, resistenza e affidabilità sono fondamentali, come quello aerospaziale, medico e automobilistico.

Quanto tempo occorre per realizzare un pezzo lavorato su misura?

A seconda della complessità, possono essere necessari da pochi giorni a diverse settimane.

Posso ordinare solo un pezzo?

Sì! SYM offre lavorazioni CNC personalizzate senza un minimo d'ordine.

Quali materiali possono essere lavorati?

Le opzioni più comuni includono alluminio, titanio, acciaio inossidabile, ottone, rame e varie materie plastiche.

Qual è la differenza tra fresatura e tornitura CNC?

La fresatura asporta materiale da un pezzo fisso utilizzando utensili rotanti, mentre la tornitura fa ruotare il pezzo contro gli utensili da taglio.

Offrite supporto alla progettazione di prototipi?

Assolutamente sì. SYM lavora a stretto contatto con i clienti per perfezionare i progetti prima della produzione.

Conclusione

Le parti lavorate di precisione su misura sono gli eroi nascosti dell'innovazione moderna. Che stiate costruendo un dispositivo medico salvavita o un drone ad alte prestazioni, il successo del vostro prodotto dipende spesso dalla precisione e dalla qualità dei suoi componenti. Dalla selezione dei materiali giusti alla scelta del processo di lavorazione migliore, ogni fase è importante.

In SYM Precision Machining, combiniamo una profonda conoscenza del settore con attrezzature all'avanguardia per fornire pezzi che soddisfino le vostre esatte esigenze. La nostra ampia gamma di servizi - da taglio CNC personalizzato a parti tornite CNC personalizzate-garantisce la migliore qualità, il miglior prezzo e i migliori tempi di consegna.

Non lasciate il vostro progetto al caso. Collaborate con esperti che hanno a cuore la precisione quanto voi.

Articoli correlati:

10 suggerimenti per la personalizzazione di parti lavorate di precisione di alta qualità

7 potenti informazioni sul costo della lavorazione CNC all'ora