Ecco una versione dettagliata dei 10 suggerimenti per la personalizzazione di parti lavorate di precisione di alta qualità.

Seguendo questi 10 consigli per la realizzazione di parti lavorate di precisione personalizzate di alta qualità, potrete ottimizzare il processo di produzione, migliorare la qualità dei pezzi e garantire il successo del vostro progetto dall'inizio alla fine. Se state progettando pezzi per il settore aerospaziale, per i dispositivi medici, per l'industria automobilistica o per qualsiasi altro settore di precisione, questi suggerimenti vi aiuteranno a superare le complessità della lavorazione personalizzata.

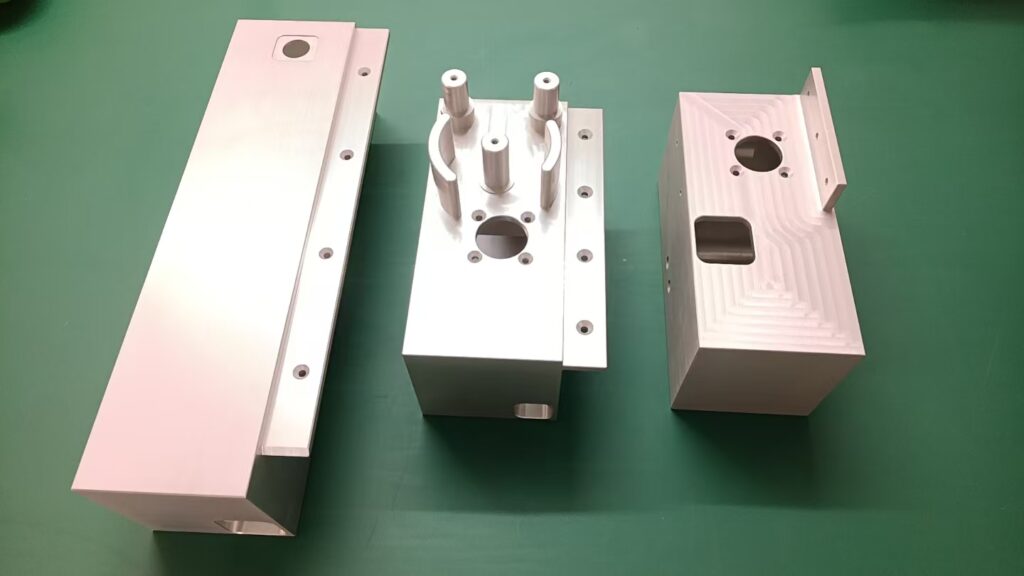

Scegliere il materiale giusto in base all'applicazione

La scelta del materiale corretto per i vostri pezzi lavorati di precisione è fondamentale per le loro prestazioni, la loro durata e la loro economicità. Applicazioni diverse richiedono proprietà diverse, come la forza, la resistenza alla corrosione o la flessibilità. Ad esempio, i componenti aerospaziali spesso richiedono materiali leggeri ma resistenti come il titanio o l'alluminio, mentre i dispositivi medici possono richiedere materiali biocompatibili come l'acciaio inossidabile o alcune materie plastiche. Consultate sempre il vostro produttore per assicurarvi che il materiale scelto funzioni in modo ottimale nelle vostre condizioni specifiche.

Lavorare con un produttore che ha esperienza nel vostro settore

L'esperienza conta quando si tratta di lavorazioni meccaniche personalizzate. Un produttore con esperienza nel vostro settore specifico comprenderà meglio i requisiti unici e le sfide che possono sorgere durante la produzione. Che si tratti di rispettare gli standard di sicurezza per il settore medico o di aderire a tolleranze rigorose per i componenti aerospaziali, un partner esperto avrà la competenza necessaria per fornire pezzi di alta qualità nei tempi e nei costi previsti.

Privilegiare il controllo qualità in ogni fase della produzione

Il controllo qualità non è solo un controllo finale, ma deve essere integrato nell'intero processo produttivo.

Dalla selezione delle materie prime alle ispezioni finali, ogni fase deve essere monitorata meticolosamente per garantire che i pezzi soddisfino le specifiche richieste. Sia che si tratti di effettuare controlli dimensionali o di verificare le proprietà dei materiali, un solido sistema di controllo della qualità garantisce che i vostri pezzi siano accurati, affidabili e sicuri per l'uso nelle vostre applicazioni.

Comprendere la ripartizione dei costi per gestire il budget in modo efficace

Comprendere la struttura dei costi della lavorazione di precisione personalizzata vi aiuterà a gestire il vostro budget in modo efficace. I costi possono variare in base a fattori quali la scelta del materiale, la complessità del pezzo, i tempi di consegna e i processi di lavorazione coinvolti.

Comprendendo l'impatto di ciascun elemento sul prezzo complessivo, è possibile prendere decisioni più consapevoli su dove investire e dove ottimizzare. Inoltre, la comprensione della ripartizione dei costi aiuta a evitare spese impreviste, che spesso possono verificarsi durante la produzione di pezzi personalizzati.

Assicurarsi che il progetto sia ottimizzato per la lavorazione di precisione

La progettazione del pezzo gioca un ruolo fondamentale nel garantire che il processo di lavorazione sia efficiente ed economico. Geometrie complesse, tolleranze eccessive o caratteristiche difficili possono aumentare i tempi e i costi di lavorazione. Lavorate a stretto contatto con il team di progettazione e ingegnerizzazione per assicurarvi che il pezzo sia ottimizzato per il processo di lavorazione. Ciò può includere la semplificazione del progetto, la regolazione delle tolleranze o la scelta di caratteristiche più facili da lavorare.

Utilizzare tecnologie avanzate come le macchine CNC per un'elevata precisione

La lavorazione CNC (Computer Numerical Control) è una tecnologia essenziale per la produzione di pezzi di alta precisione. Le macchine CNC sono in grado di ottenere tolleranze strette e risultati ripetibili, il che le rende ideali per i settori che richiedono precisione e coerenza.

Inoltre, le macchine CNC più recenti offrono funzionalità avanzate come la lavorazione su più assi e ad alta velocità, che possono migliorare la qualità dei pezzi e ridurre i tempi di consegna.

Ispezione visiva e funzionale delle parti prima della consegna

Prima che i pezzi vengano spediti, è necessaria un'ispezione approfondita per garantire che siano conformi alle specifiche richieste. Ciò comporta sia un'ispezione visiva per individuare eventuali difetti estetici (come graffi, crepe o imperfezioni superficiali) sia test funzionali per confermare che i pezzi funzionino come previsto. A seconda dell'applicazione del pezzo, possono essere utilizzati anche metodi di controllo non distruttivi (NDT), come l'ispezione a ultrasuoni o a raggi-X.

Prevedere tempi di consegna più lunghi per le parti personalizzate

I pezzi lavorati di precisione su misura spesso richiedono tempi di consegna più lunghi a causa della loro complessità e della necessità di attrezzature o materiali specializzati. Assicuratevi di pianificare in anticipo e di comunicare le tempistiche del progetto con il vostro produttore fin dalle prime fasi.

Questo vi aiuterà a gestire le aspettative e a evitare ritardi nel programma di produzione. Se le scadenze sono strette, è fondamentale discutere in anticipo le opzioni di produzione accelerata.

Collaborare strettamente con il vostro produttore per risolvere i problemi

Una comunicazione chiara con il produttore è fondamentale per superare qualsiasi problema durante il processo di produzione. Che si tratti di un problema di progettazione, di un problema di materiali o di un ritardo imprevisto, affrontare i problemi in modo rapido e collaborativo garantisce una produzione senza intoppi. Costruire un solido rapporto di lavoro con il produttore significa avere un partner affidabile in grado di risolvere i problemi e fornire consigli durante tutto il processo.

Rimanere aggiornati sulle tendenze e le innovazioni della lavorazione di precisione

La lavorazione di precisione è un campo in continua evoluzione, con tecnologie e materiali sempre nuovi. Tenetevi informati sulle ultime tendenze della lavorazione, come la produzione additiva, l'automazione o i progressi nella scienza dei materiali, per garantire che i vostri pezzi siano sempre all'avanguardia. Rimanendo aggiornati, potrete approfittare delle innovazioni che possono ridurre i costi, migliorare la qualità o addirittura creare nuove possibilità per i vostri prodotti.