Esplora perché Componenti lavorati di livello aerospaziale sono fondamentali per l'industria aeronautica e spaziale. Scoprite i loro materiali, la precisione e le applicazioni.

Introduzione ai componenti lavorati di livello aerospaziale

I componenti aerospaziali non sono i soliti pezzi di metallo. Sono costruiti per altitudini, velocità, temperature e aspettative estreme. Questi componenti devono essere incredibilmente leggeri ma anche super resistenti. Anche il più piccolo bullone o staffa deve rispettare tolleranze incredibilmente strette.

Cosa rende un pezzo "di livello aerospaziale"? Per cominciare, i materiali devono resistere alla corrosione, alla fatica e alle forti sollecitazioni termiche. Poi, il processo di produzione deve essere a dir poco impeccabile. E tutto ciò deve essere conforme a certificazioni globali come AS9100.

L'importanza dei componenti di grado aerospaziale non può essere sopravvalutata. Garantiscono la sicurezza di milioni di passeggeri delle compagnie aeree ogni giorno, aiutano i veicoli spaziali a raggiungere l'orbita e supportano persino i droni durante le missioni di sorveglianza ad alta velocità. Quando questi componenti funzionano perfettamente, nessuno se ne accorge. Ma se qualcosa va storto, le conseguenze possono essere disastrose.

Ecco perché la lavorazione aerospaziale è uno dei settori più rispettati ed esigenti della produzione moderna. Questi componenti sono spesso costruiti su misura, secondo standard rigorosi che non lasciano spazio a scorciatoie. Che si tratti di una pala di un motore a reazione o di una parte di un satellite, ogni pezzo deve adattarsi perfettamente e funzionare senza problemi. La richiesta di precisione ha portato alla nascita di tecnologie di produzione avanzate, in particolare la lavorazione CNC.

In questo articolo, faremo un viaggio nell'eccitante ed esigente mondo della produzione aerospaziale, analizzando le tecniche chiave, i materiali, le sfide e le innovazioni che definiscono questo settore all'avanguardia. Quindi, allacciate le cinture: è qui che i sogni aerospaziali diventano realtà, un micrometro alla volta.

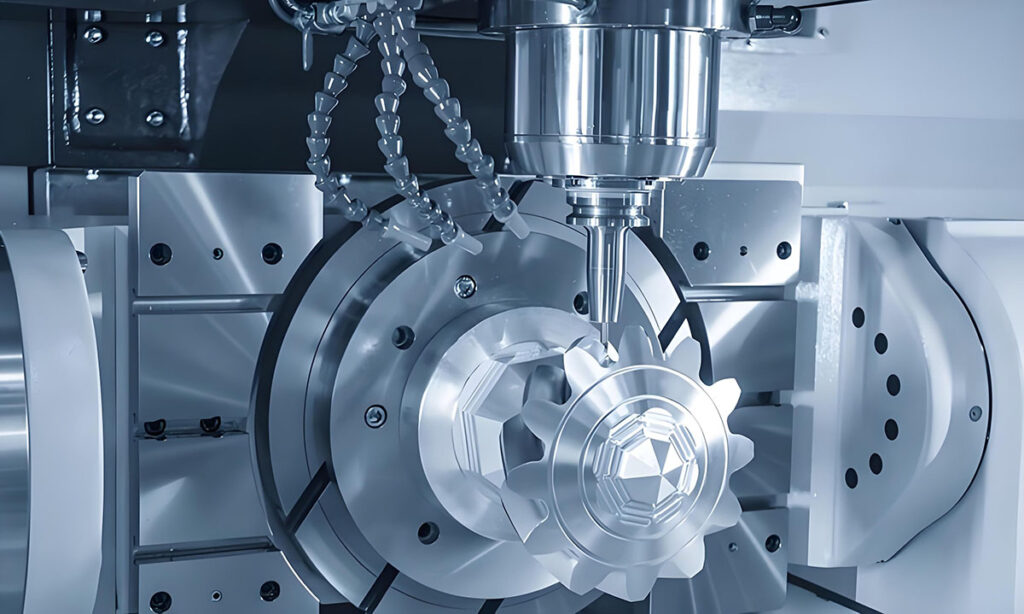

Tecniche avanzate di lavorazione CNC per parti aerospaziali

Quando si costruiscono componenti per il cielo e oltre, non ci si può accontentare di una lavorazione di base. È qui che tecniche avanzate di CNC entrare.

Lavorazione CNC a 5 assi è lo standard di riferimento nel settore aerospaziale. Consente il movimento simultaneo in più direzioni, creando geometrie complesse in un'unica configurazione. Questo non solo aumenta l'efficienza, ma garantisce una precisione quasi impossibile con le macchine più vecchie.

Elettroerosione a filo (lavorazione a scarica elettrica) è utilizzato per tagli incredibilmente fini nei metalli duri. Si pensi agli ugelli del carburante o ai piccoli alloggiamenti dei sensori.

Lavorazione svizzeraIl materiale di cui è composto, originariamente utilizzato per i componenti degli orologi, è perfetto per i piccoli componenti aerospaziali, come perni e distanziali. Le tolleranze strette e le finiture lisce ne fanno una scelta obbligata.

Fresatura di precisione e tornitura ad alta velocità completano la gamma di strumenti. Ogni metodo viene scelto in base al materiale, alla complessità del pezzo e ai requisiti di utilizzo finale.

Queste tecnologie contribuiscono a ridurre l'errore umano e ad aumentare l'uniformità dei pezzi, un requisito indispensabile nel settore aerospaziale. Ma non solo: la lavorazione CNC accelera anche la produzione e migliora l'utilizzo dei materiali, rendendola efficiente ed ecologica.

La programmazione CNC avanzata comprende anche simulazioni e monitoraggio in tempo reale, in modo che i macchinisti possano individuare gli errori prima che si verifichino. È una fusione intelligente di software, meccanica e competenze umane che trasforma materie prime di livello aerospaziale in componenti di alto livello in grado di affrontare i cieli e oltre.

Materiali chiave utilizzati nei componenti di livello aerospaziale

La resistenza dei componenti aerospaziali è pari a quella dei materiali con cui sono realizzati. Ecco perché la scelta di quello giusto è fondamentale. I componenti aerospaziali devono essere leggeri, durevoli, resistenti al calore e alla corrosione. Non si tratta di materiali comuni, ma di leghe ad alte prestazioni progettate specificamente per il volo e lo spazio.

| Materiale | Proprietà | Uso tipico |

| Titanio | Leggero, resistente alla corrosione, elevato rapporto forza-peso | Parti del motore, carrello di atterraggio |

| Leghe di alluminio | Facile da lavorare, economico, di discreta resistenza | Componenti strutturali, alloggiamenti |

| Inconel (leghe a base di nichel) | Estrema resistenza al calore, difficile da lavorare | Pale di turbina, sistemi di scarico |

| Acciaio inox | Durevole, resistente alla corrosione | Staffe, sensori, connettori |

| Compositi (fibra di carbonio) | Molto leggero, resistente, non metallico | Radome, pannelli della fusoliera |

La lavorazione di questi materiali non è una passeggiata. Il titanio e l'inconel sono notoriamente difficili da lavorare, generano calore e consumano rapidamente gli utensili. Per questo motivo i macchinisti utilizzano utensili personalizzati, sistemi di raffreddamento e velocità di taglio ridotte.

Ogni materiale ha una "personalità" unica quando si tratta di lavorazione. Capire come si comportano durante il taglio aiuta i produttori a mantenere l'accuratezza e a prolungare la durata degli utensili, due aspetti molto importanti nelle applicazioni aerospaziali.

Tolleranze e standard di qualità nella lavorazione aerospaziale

Nel settore aerospaziale la perfezione non è un obiettivo, ma un requisito. Le tolleranze strette sono la norma, non l'eccezione. Ciò significa che un pezzo deve essere lavorato per rientrare nel più piccolo margine di errore possibile. Stiamo parlando di tolleranze spesso più strette di ±0,001 pollici.

I componenti lavorati di livello aerospaziale sono soggetti a standard rigorosi come:

- AS9100: Uno standard di gestione della qualità ampiamente adottato dall'industria aerospaziale.

- ISO 9001: Assicura una qualità costante in tutta la produzione.

- Certificazione NADCAP: Si concentra in particolare su processi speciali come il trattamento termico e i controlli non distruttivi.

- Conformità FAA: Critico per i componenti dei voli commerciali.

Queste certificazioni assicurano che ogni componente soddisfi gli standard di prestazione e sicurezza. Inoltre, rendono più facile per gli OEM del settore aerospaziale fidarsi dei propri fornitori. Per soddisfare questi standard, i produttori utilizzano:

- Macchine di misura a coordinate (CMM): Per ispezionare le geometrie con precisione millimetrica.

- Ispezioni del primo articolo (FAI): Richiesto per convalidare la prima parte di ogni nuovo ciclo di produzione.

- Controlli non distruttivi (NDT): Per trovare i difetti senza danneggiare il componente.

L'assicurazione di qualità non è solo una questione di spunta, ma anche di fiducia. Dopotutto, ogni volta che un aereo decolla, da questi componenti dipendono vite umane.

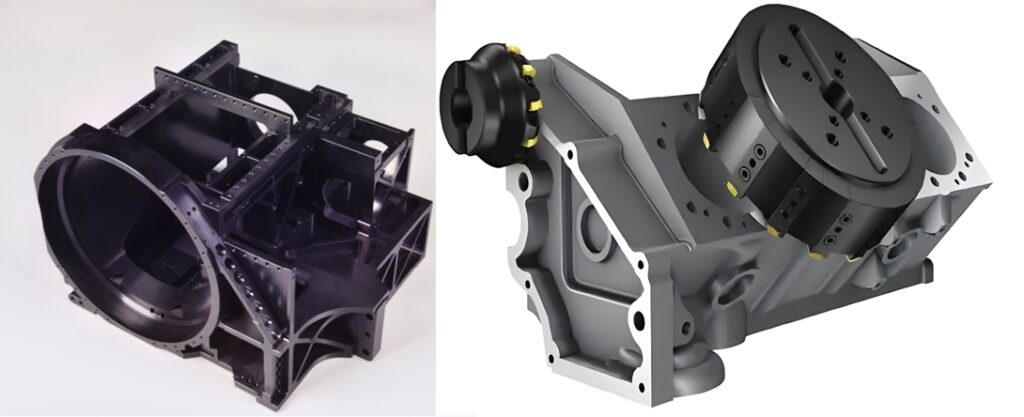

Considerazioni sulla progettazione di parti lavorate in ambito aerospaziale

Progettare per il settore aerospaziale non significa solo realizzare qualcosa che vada bene: si tratta di ottimizzare le prestazioni, il peso e la sicurezza.

Uno degli obiettivi più importanti? Alleggerimento. Ogni grammo risparmiato in un aereo può ridurre il consumo di carburante e le emissioni. Ecco perché materiali come il titanio e la fibra di carbonio sono così preziosi.

Un altro fattore è controllo della tolleranza. I componenti aerospaziali richiedono spesso tolleranze di ±0,002 mm. Queste tolleranze contribuiscono a garantire l'affidabilità in presenza di vibrazioni, pressione e variazioni di temperatura.

I progettisti devono anche pensare a espansione termica, smorzamento delle vibrazioni, e integrità strutturale. Ad esempio, una staffa apparentemente semplice potrebbe necessitare di nervature interne o filetti per evitare cricche da fatica nel corso del tempo.

Il software CAM trasforma i progetti digitali in codice leggibile dalla macchina. Con questi strumenti, gli ingegneri possono creare superfici complesse e verificarle prima di eseguire un singolo taglio. In questo modo si riducono le rilavorazioni, si migliora la finitura superficiale e si aumenta la precisione dei pezzi.

- Progettare parti ultra complesse con dettagli di livello millimetrico

- Simulazione dei percorsi di taglio e identificazione degli errori prima dell'inizio della lavorazione

- Ottimizzazione dell'uso del materiale e riduzione dei tempi di lavorazione

- Programmare macchine CNC multiasse con istruzioni personalizzate

Le migliori piattaforme CAD/CAM, come Mastercam, Siemens NX e Fusion 360, sono un punto fermo nelle officine aerospaziali. Permettono ai macchinisti di spingersi oltre i limiti del possibile, dalla progettazione di complesse pale di turbina alla fabbricazione di connettori satellitari su microscala.

Tecniche di finitura superficiale per parti aerospaziali

La finitura superficiale non è solo estetica, ma anche funzionale, durevole e aerodinamica. Nel settore aerospaziale, la finitura può influire su tutto, dal flusso d'aria alla resistenza alla corrosione. Ecco una panoramica di alcuni dei trattamenti superficiali più comunemente utilizzati:

| Tecnica | Scopo | Uso comune |

| Anodizzazione | Migliora la resistenza alla corrosione e la durezza superficiale | Parti aeronautiche in alluminio |

| Passivazione | Rimuove i contaminanti per prevenire la corrosione | Elementi di fissaggio in acciaio inox |

| Pallinatura | Migliora la durata a fatica inducendo una tensione di compressione. | Ingranaggi, componenti del motore |

| Elettrolucidatura | Migliora la microfinitura e rimuove le sbavature | Componenti medicali e aerospaziali di precisione |

| Spruzzatura al plasma | Aggiunge strati di protezione termica | Pale di turbina |

Ogni metodo di finitura deve essere in linea con il materiale e la sua funzione. Ad esempio, un componente destinato al calore elevato deve resistere all'ossidazione, mentre uno destinato a carichi strutturali potrebbe richiedere una maggiore resistenza alla fatica. Gli esperti di lavorazione considerano questi requisiti fin dalle prime fasi del processo per garantire la compatibilità.

Sfide nella produzione di componenti di livello aerospaziale

Siamo onesti: la produzione di componenti aerospaziali non è facile. È uno dei settori più impegnativi della produzione. Ecco le sfide principali:

- Proprietà estreme del materiale: I metalli aerospaziali come l'Inconel o il titanio sono resistenti, ma la loro durezza rende difficile la lavorazione. Gli utensili da taglio si consumano rapidamente e l'accumulo di calore può deformare i pezzi.

- Tolleranze strette: Anche un millesimo di pollice può fare la differenza tra successo e fallimento. La precisione non è negoziabile.

- Geometrie complesse: I pezzi hanno spesso bisogno di canali interni, angoli composti o raggi stretti. Questi richiedono una lavorazione multiasse e un'attenta pianificazione.

- Conformità normativa: Certificazioni come la AS9100 o la conformità FAA richiedono documentazione, ispezioni e tracciabilità approfondite.

- Il costo elevato degli errori: Il materiale di scarto non è solo un costo, ma può causare ritardi nella produzione o addirittura problemi di sicurezza.

I macchinisti esperti superano queste sfide sfruttando software di simulazione, utensili ad alte prestazioni e pianificazione collaborativa tra ingegneri e macchinisti. Strategie intelligenti e le attrezzature giuste rendono possibile il successo.

Applicazioni dei componenti lavorati di grado aerospaziale

I componenti lavorati in ambito aerospaziale costituiscono la spina dorsale invisibile di ogni meraviglia aerea e spaziale. Questi componenti entrano a far parte di:

- Motori a reazione: Dalle pale delle turbine ai componenti del sistema di alimentazione, tutti devono sopportare temperature e pressioni estreme.

- Sistemi avionici: I connettori, le custodie e le staffe, minuscoli ma potenti, sono tutti lavorati con precisione per garantire precisione e sicurezza.

- Sistemi di carrello d'atterraggio: Questi componenti sono sottoposti a enormi carichi d'urto e necessitano di una resistenza eccezionale.

- Fusoliera e ali: I componenti strutturali lavorati in alluminio o titanio migliorano il rapporto resistenza/peso dell'aereo.

- Satelliti e veicoli spaziali: I componenti leggeri che resistono al vuoto e alle radiazioni devono soddisfare requisiti di precisione straordinari.

Nelle applicazioni di difesa, questi componenti svolgono un ruolo nei veicoli aerei senza pilota (UAV), nei missili e nei sistemi di sorveglianza. Non è esagerato dire che le prestazioni di un intero velivolo dipendono spesso dalla qualità delle sue parti lavorate. Senza di essi, nessuna delle imprese di volo che abbiamo imparato ad ammirare sarebbe possibile.

Tendenze future nella lavorazione aerospaziale

Il cielo non è il limite, è solo l'inizio. La lavorazione aerospaziale continua ad evolversi. Diamo un'occhiata al futuro:

- Lavorazione con intelligenza artificiale: Gli algoritmi predittivi che regolano l'alimentazione e la velocità in tempo reale stanno diventando uno standard.

- Produzione ibrida: La combinazione della lavorazione CNC con la stampa 3D consente di velocizzare la prototipazione e la progettazione di pezzi complessi.

- Gemelli digitali: I modelli virtuali di parti fisiche vengono utilizzati per ottimizzare la produzione e la manutenzione.

- Lavorazione sostenibile: Il riciclaggio dei refrigeranti, la riduzione dei rifiuti di materiale e le pratiche di energia verde stanno diventando sempre più diffuse.

- Nano-lavorazione: Con il boom della miniaturizzazione, la precisione su scala nanometrica sta diventando sempre più importante.

Con l'espansione dell'industria aerospaziale verso i voli spaziali commerciali e gli UAV avanzati, i processi di lavorazione devono tenere il passo. Restare al passo significa adattarsi a queste innovazioni.

Perché scegliere un partner affidabile per la lavorazione aerospaziale?

Non tutte le officine meccaniche sono in grado di offrire una qualità di livello aerospaziale. La scelta del partner giusto è essenziale.

Un buon fornitore aerospaziale offre molto di più della semplice lavorazione: fornisce supporto ingegneristico, approvvigionamento dei materiali, e controllo di qualità end-to-end.

Cercate officine con strutture pulite, attrezzature moderne ed esperienza con i contratti aerospaziali. I casi di studio, le testimonianze dei clienti e i risultati delle revisioni possono aiutare a distinguere i professionisti da chi non lo fa.

Un partner forte vi aiuterà a semplificare la progettazione, a ridurre i costi e a rispettare le scadenze più strette senza compromettere la qualità.

Ecco un partner affidabile per la lavorazione aerospaziale

Nel settore aerospaziale, l'affidabilità non è un optional: è un obbligo. Ecco perché le aziende di tutto il mondo si affidano a SYM Lavorazione di precisione come partner di riferimento per i componenti lavorati di livello aerospaziale.

Perché SYM si distingue nella lavorazione CNC del settore aerospaziale

SYM Precision Machining combina una tecnologia all'avanguardia con anni di esperienza per soddisfare gli esigenti requisiti del settore aerospaziale. Ecco cosa rende SYM un partner di fiducia per la lavorazione aerospaziale:

- Sistemi di qualità certificati:

SYM opera nell'ambito di rigorosi sistemi di gestione della qualità, tra cui ISO 9001:2015 e protocolli specifici per il settore aerospaziale. Ogni componente aerospaziale viene sottoposto a un rigoroso processo di ispezione con l'ausilio di macchine di misura ad alta precisione, per garantire una qualità costante e una tracciabilità completa. - Apparecchiature avanzate per parti complesse:

Da Fresatura CNC a 5 assi a centri di tornitura multitasking e elettroerosione a filoL'officina SYM è dotata dei macchinari avanzati necessari per gestire geometrie aerospaziali complesse e tolleranze strettissime. - Competenza nei materiali aerospaziali:

SYM ha una profonda esperienza nella lavorazione di materiali di grado aerospaziale come Titanio, Inconel, Alluminio 7075/6061, e Acciaio inox 17-4PH. Il team sa come lavorare queste leghe ad alte prestazioni mantenendo la precisione dimensionale e l'integrità della superficie. - Controllo di tolleranza rigoroso:

I pezzi aerospaziali richiedono spesso tolleranze di ±0,005 mm. SYM è in grado di offrire precisione, grazie all'ispezione in-process, alla programmazione professionale dei percorsi utensile e agli ambienti a clima controllato che riducono al minimo le variazioni dimensionali. - Supporto ingegneristico reattivo:

Gli ingegneri di SYM lavorano a stretto contatto con i clienti durante la fase di DFM (Design for Manufacturability) offrendo suggerimenti preziosi che migliorano le prestazioni e la producibilità dei pezzi, controllando i costi e i tempi di consegna. - Volume di produzione flessibile:

Se avete bisogno di un singolo prototipo per i test o Oltre 500 unità di produzione per una linea di assemblaggio aerospaziale, SYM può scalare i suoi servizi senza compromettere la qualità o i tempi di consegna. - Documentazione completa e conformità:

I progetti aerospaziali richiedono una documentazione come Rapporti di ispezione del primo articolo (FAI), certificazioni dei materiali, e registri di tracciabilità. SYM fornisce pacchetti di documentazione completi come parte del suo processo standard per i clienti del settore aerospaziale.

Applicazioni aerospaziali del mondo reale

SYM ha lavorato con successo componenti utilizzati in:

- Sottosistemi satellitari

- Sistemi di propulsione per droni

- Alloggiamenti per avionica

- Supporti strutturali interni dell'aeromobile

- Supporti motore e sistemi di raffreddamento

Ogni componente è realizzato con la massima attenzione per garantire prestazioni affidabili in applicazioni critiche.

Fiducia dei clienti del settore aerospaziale globale

SYM serve clienti del settore aerospaziale in tutto il Stati Uniti, Europa e Asiaoffrendo una comunicazione rapida, consegne puntuali e un'assistenza post-vendita reattiva. Con Ingegneri di vendita che parlano inglese, rapida esecuzione del preventivo, e esperienza di logistica internazionaleSYM elimina gli attriti dalle catene di fornitura globali.

Se siete alla ricerca di un partner affidabile per la lavorazione aerospaziale che comprenda le aspettative di precisione, conformità e prestazioni del settore, SYM Lavorazione di precisione è il fornitore su cui potete contare-Dal prototipo alla produzione.

Domande frequenti

Quali sono i materiali più comunemente utilizzati nella lavorazione CNC del settore aerospaziale?

Il titanio, le leghe di alluminio, l'acciaio inossidabile, l'Inconel e i compositi in fibra di carbonio sono i più comuni grazie alla loro resistenza e leggerezza.

Perché la precisione è così importante nei componenti aerospaziali?

Anche il più piccolo errore dimensionale può causare un guasto in ambienti ad alta sollecitazione, che potrebbe essere catastrofico in volo o nello spazio.

In che modo la lavorazione CNC è utile nella produzione aerospaziale?

Permette di produrre pezzi complessi e con tolleranze ristrette in modo rapido e ripetibile, garantendo qualità e prestazioni.

La lavorazione aerospaziale è più costosa di quella normale?

Sì, a causa delle tolleranze più strette, dei materiali di qualità superiore, delle geometrie complesse e delle severe norme di conformità.

La stampa 3D può sostituire la lavorazione CNC nel settore aerospaziale?

Non del tutto. Sebbene la produzione additiva sia utile per la prototipazione o per alcuni progetti, la lavorazione CNC rimane il gold standard per la resistenza e la precisione.

Quali certificazioni sono necessarie per le aziende di lavorazione aerospaziale?

Certificazioni come AS9100, ISO 9001, NADCAP e l'approvazione FAA sono essenziali per garantire la qualità e la conformità normativa.

Conclusione

I componenti lavorati in ambito aerospaziale sono più che semplici pezzi: sono linee di vita in un mondo in cui l'affidabilità è tutto. Dalla scelta dei materiali giusti all'utilizzo di tecniche CNC avanzate, ogni fase è cruciale. Che si tratti di una pala di turbina o di una staffa per satellite, questi componenti rappresentano l'apice dell'ingegneria umana.

Mentre continuiamo a esplorare nuove frontiere, dai viaggi spaziali commerciali al volo ipersonico, la lavorazione aerospaziale di precisione rimarrà una pietra miliare dell'innovazione. Non si tratta solo di metallo e macchine, ma del futuro che stiamo costruendo, un pezzo perfetto alla volta.