Découvrez pourquoi l'usinage de précision sur mesure est essentiel pour une fabrication précise, fiable et performante. Apprenez à choisir les matériaux, à réduire les coûts et à travailler avec le bon partenaire d'usinage CNC.

Introduction à l'usinage de précision sur mesure

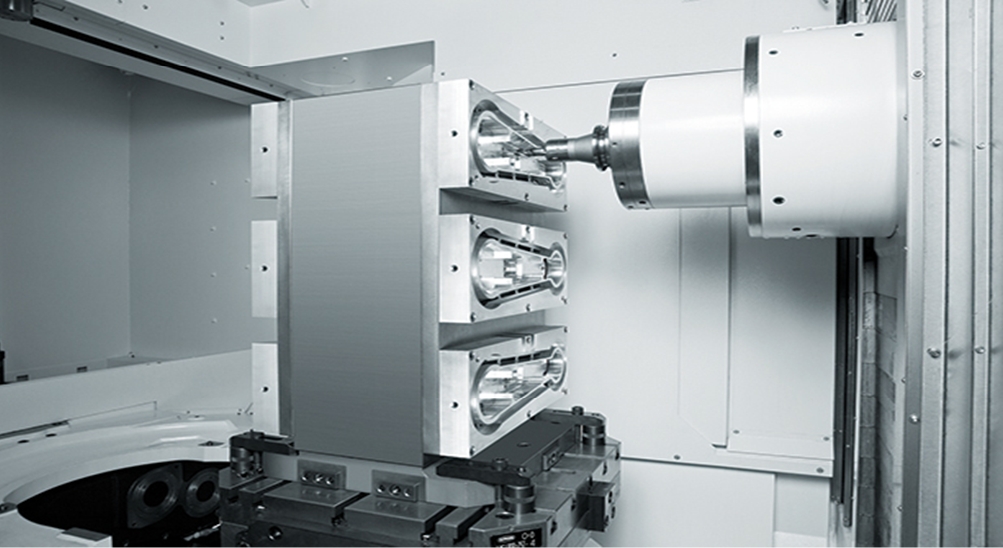

Usinage de précision sur mesure est un processus de fabrication spécialisé qui consiste à créer des pièces ou des composants très précis, complexes et conçus sur mesure pour répondre à des spécifications exactes. Il utilise des techniques d'usinage avancées, des tolérances serrées et des matériaux de haute qualité pour produire des pièces d'une précision et d'une répétabilité exceptionnelles.

Les pièces usinées de précision sur mesure sont les éléments constitutifs de la fabrication moderne. Dans des secteurs comme l'aérospatiale, l'automobile, les appareils médicaux ou la robotique, la précision est essentielle.

Pourquoi choisir le sur-mesure ? Parce qu'il n'existe pas deux projets identiques. Vous avez besoin de matériaux, de formes et de tolérances spécifiques que les pièces standard ne peuvent pas offrir. C'est là qu'interviennent les services expérimentés d'usinage CNC sur mesure.

Dans ce guide, nous vous expliquons tout ce que vous devez savoir, depuis le choix des bons matériaux et la compréhension des facteurs de coût jusqu'à la recherche d'un partenaire d'usinage fiable. Nous vous montrerons également pourquoi SYM Precision Machining est un nom de confiance lorsqu'il s'agit de pièces de précision personnalisées pour les petites séries ou la production en grande quantité.

Pourquoi la précision est-elle importante ?

Pensez à un travail de découpe de métal CNC sur mesure pour un moteur aérospatial. Si la pièce est décalée d'une fraction seulement, cela peut entraîner une défaillance du système. Ou encore, pensez aux pièces tournées CNC personnalisées d'un implant médical. Ces pièces doivent être biocompatibles et parfaitement adaptées à l'anatomie du patient.

La précision n'est pas seulement une question d'esthétique, c'est aussi une question de sécurité, de fonctionnalité et de performance.

Types d'usinage de précision sur mesure

- Usinage CNC sur mesure: Utilise des outils automatisés pour enlever de la matière d'une pièce.

- Service de fraisage CNC sur mesure: Une fraise rotative enlève le matériau - idéal pour les surfaces planes ou les caractéristiques angulaires.

- Pièces de tournage CNC sur mesure: Utilisé pour fabriquer des composants cylindriques avec une symétrie de rotation.

- Découpe CNC sur mesure: Les outils à grande vitesse découpent avec précision des métaux tels que l'aluminium et le titane.

Chaque technique répond à un besoin différent et, souvent, plusieurs d'entre elles sont combinées pour obtenir une solution complète.

Matériaux utilisés dans l'usinage de précision sur mesure

Le choix du bon matériau est la première étape - et l'une des plus importantes - de la création d'une pièce de précision réussie. Les performances, le coût, l'usinabilité et même la durée de vie d'une pièce dépendent tous de la sélection du matériau.

Matériaux populaires pour les pièces de précision sur mesure

| Matériau | Caractéristiques | Utilisations courantes |

| Aluminium | Léger, résistant à la corrosion, facile à usiner | Drones, électronique, automobile |

| Titane | Rapport résistance/poids élevé, biocompatible | Aérospatiale, implants médicaux |

| Acier inoxydable | Solide, résistant à la corrosion | Marine, agroalimentaire, automobile |

| Plastiques (par exemple, PEEK, Delrin) | Léger, résistant aux produits chimiques | Médical, électronique, prototypage |

Éléments à prendre en compte lors du choix des matériaux

- Exigences en matière de candidature: La pièce doit-elle résister à une chaleur élevée ou à la corrosion ?

- Budget: L'aluminium est moins cher que le titane mais peut ne pas répondre aux besoins de résistance.

- Tolérance: Certains matériaux sont plus faciles à usiner avec des tolérances serrées.

Avec le SYM services d'usinage de précision sur mesurevous pouvez obtenir des conseils d'experts sur la sélection des matériaux en fonction de votre application unique.

Considérations relatives à la conception des pièces usinées

Vous pouvez avoir le meilleur atelier d'usinage du monde, mais si votre conception n'est pas optimisée pour l'usinage, cela pourrait vous coûter plus de temps et d'argent que nécessaire. C'est pourquoi la conception pour la fabrication (DFM) est si importante dans les domaines suivants usinage de précision sur mesure.

Conseils pour optimiser votre design

- Minimiser les angles vifs: Utiliser les congés et les rayons pour réduire l'usure de l'outil et accélérer l'usinage.

- Simplifier la géométrie: Plus la conception est simple, plus le coût et le délai d'exécution sont réduits.

- Appeler les caractéristiques critiques uniquement: Ne pas sur-spécifier les tolérances à moins que cela ne soit nécessaire.

Pourquoi les modèles CAO sont-ils importants ?

Des modèles CAO détaillés permettent aux machines CNC de suivre le plan avec une extrême précision. Assurez-vous que vos fichiers sont à jour et qu'ils contiennent des informations complètes, ce qui est particulièrement vrai pour les pièces de fraisage et de tournage CNC personnalisées.

Besoin d'aide pour affiner votre design ? SYM propose Pièces d'usinage CNC personnalisées et travaille en étroite collaboration avec les ingénieurs pour détecter les problèmes avant le début de la production.

Comment fonctionnent les services d'usinage CNC sur mesure ?

Les services d'usinage CNC personnalisés sont l'épine dorsale de la fabrication de précision. Qu'il s'agisse de créer un prototype unique ou de passer à la production complète, la compréhension du processus vous aide à prendre des décisions plus judicieuses.

Processus d'usinage CNC étape par étape

- Soumission des dessins et modèles

Vous commencez par envoyer un dessin en 2D ou un fichier CAO en 3D au fournisseur de services d'usinage. - Sélection des matériaux

Le magasin examine vos spécifications et vous aide à choisir un matériau approprié (aluminium, titane ou acier inoxydable). - Programmation FAO

Le logiciel de FAO (fabrication assistée par ordinateur) traduit le modèle CAO en trajectoires d'outils. - Configuration de la machine

La machine CNC est chargée d'outils et de matériaux, puis calibrée pour une découpe précise. - Usinage et inspection

La pièce est découpée selon les spécifications, puis inspectée pour le contrôle de la qualité à l'aide de micromètres, de MMT ou de scanners laser. - Finition et livraison

Des procédés optionnels tels que l'anodisation, le revêtement par poudre ou le polissage sont appliqués avant l'expédition de la pièce.

Différents types de services

- Service de fraisage CNC sur mesure: Idéal pour les surfaces planes ou profilées.

- Pièces de tournage CNC sur mesure: Idéal pour les formes cylindriques.

- Découpe de métal CNC sur mesure: Découpe précise de métaux tels que l'acier inoxydable, le titane ou le cuivre.

Service CNC personnalisé pour le prototypage: Délai d'exécution rapide pour la validation de la conception.

Au SYM Precision MachiningEn outre, tous ces services sont regroupés sous un même toit, depuis les prototypes à rotation rapide jusqu'à la production à grande échelle.

Comprendre les coûts de l'usinage CNC sur mesure

Savoir ce qui entre en ligne de compte dans la fixation du prix des usinage CNC sur mesure peut vous aider à établir un meilleur budget et à éviter les surprises.

Facteurs influençant les coûts d'usinage CNC

| Facteur | Description |

| Type de matériau | Le titane est plus cher que l'aluminium ou le plastique. |

| Complexité des pièces | Les conceptions complexes nécessitent plus de temps et d'outillage. |

| Exigences de tolérance | Des tolérances plus strictes signifient un usinage plus lent et davantage d'inspections. |

| Finition | Les revêtements ou les traitements augmentent le coût. |

| Volume | Les commandes plus importantes bénéficient d'un meilleur prix à l'unité. |

Comment réduire vos coûts d'usinage ?

- Simplifiez votre conception.

- Évitez les tolérances très étroites, sauf en cas de nécessité.

- Choisissez des matériaux rentables.

- Regroupez les pièces similaires en lots pour bénéficier de remises sur les volumes.

Besoin d'un devis ? SYM offre Services d'usinage CNC sur mesure avec des prix transparents et sans quantités minimales de commande.

Avantages de choisir le bon partenaire pour l'usinage à façon

Lorsqu'il s'agit de usinage de précision sur mesureLe choix d'un partenaire peut faire de votre projet un succès ou un échec. Voici pourquoi c'est important.

- Une qualité constante

Le bon atelier utilise des outils d'inspection tels que les MMT pour s'assurer que chaque pièce est conforme à vos spécifications. - Livraison dans les délais

Les retards coûtent de l'argent. Les ateliers expérimentés comme SYM respectent les délais. - Soutien à la conception

Un bon partenaire vous aide à affiner votre conception pour réduire les coûts et améliorer les performances. - Formats de commande flexibles

Que vous ayez besoin d'une pièce ou de 10 000, ils sont prêts à vous aider. - Approvisionnement en matériaux

Ils peuvent s'approvisionner en matériaux de haute qualité tels que l'aluminium aérospatial ou le titane de qualité médicale.

Chez SYM, nous sommes fiers d'être un fournisseur digne de confiance et expérimenté dans les domaines suivants pièces usinées de précision sur mesure. A partir de usinage du titane sur mesure à Services CNC personnalisés pour l'aluminiumNous avons tout vu et mieux usiné.

Applications des composants de précision sur mesure dans tous les secteurs d'activité

Les composants usinés sur mesure sont utilisés partout, des voitures aux outils chirurgicaux. Voyons ce qu'il en est par secteur d'activité.

| L'industrie | Application | Matériau couramment utilisé |

| Aérospatiale | Pièces de moteur, composants structurels | Titane, aluminium |

| Médical | Implants, outils chirurgicaux | Acier inoxydable, PEEK |

| Automobile | Engrenages, carters de moteur | Aluminium, acier |

| Robotique | Joints et supports sur mesure | Aluminium, titane |

| Électronique | Dissipateurs thermiques, boîtiers | Cuivre, plastiques |

Avec le bon service CNC personnalisévous pouvez créer des composants adaptés à n'importe quelle application, en améliorant l'ajustement, la durabilité et la performance.

Pourquoi choisir SYM pour l'usinage de précision sur mesure ?

Lorsqu'il s'agit de usinage sur mesure près de chez moiSYM Precision Machining se distingue. Voici ce qui nous différencie :

Nos atouts

- Une équipe expérimentée: Des décennies de connaissances pratiques dans de multiples secteurs.

- Pas de minimum de commande: De la pièce unique à la série complète.

- Inventaire des matériaux: Entrepôt complet d'aluminium, de titane et d'acier inoxydable.

- Assurance qualité: Chaque pièce fait l'objet d'une inspection détaillée avant d'être livrée.

- Délai d'exécution rapide: Nous agissons rapidement sans prendre de raccourcis.

SYM est plus qu'un simple atelier d'usinage. Nous sommes votre partenaire de fabrication - nous vous aidons à concevoir, développer et livrer des pièces sur mesure qui fonctionnent parfaitement dès le départ.

FAQ

À quoi servent les pièces usinées de précision sur mesure ?

Ils sont utilisés dans des secteurs où la précision, la résistance et la fiabilité sont essentielles, comme l'aérospatiale, le secteur médical et l'automobile.

Combien de temps faut-il pour fabriquer une pièce usinée sur mesure ?

En fonction de la complexité, cela peut prendre de quelques jours à plusieurs semaines.

Puis-je commander une seule pièce ?

Oui ! SYM offre des services d'usinage CNC sur mesure sans quantité minimale de commande.

Quels matériaux peuvent être usinés ?

Les options les plus courantes sont l'aluminium, le titane, l'acier inoxydable, le laiton, le cuivre et divers plastiques.

Quelle est la différence entre le fraisage et le tournage CNC ?

Le fraisage enlève la matière d'une pièce fixe à l'aide d'outils rotatifs, tandis que le tournage fait tourner la pièce contre des outils de coupe.

Proposez-vous une aide à la conception de prototypes ?

Absolument. SYM travaille en étroite collaboration avec ses clients pour affiner les conceptions avant la production.

Conclusion

Les pièces usinées de précision sur mesure sont les héros cachés de l'innovation moderne. Que vous construisiez un appareil médical destiné à sauver des vies ou un drone haute performance, le succès de votre produit dépend souvent de la précision et de la qualité de ses composants. De la sélection des bons matériaux au choix du meilleur processus d'usinage, chaque étape compte.

Chez SYM Precision Machining, nous combinons une connaissance approfondie de l'industrie avec un équipement de pointe pour fournir des pièces qui répondent exactement à vos besoins. Notre large gamme de services - de découpe CNC sur mesure à Pièces tournées CNC sur mesure-vous garantit la meilleure qualité, le meilleur prix et le meilleur délai d'exécution.

Ne laissez pas votre projet au hasard. Associez-vous à des experts qui se soucient autant que vous de la précision.

Articles connexes :

10 conseils pour la fabrication de pièces usinées de précision de haute qualité