Mecanizado CNC de plásticos PEEK: Una guía para la precisión avanzada de polímeros

Aprenda todo sobre el mecanizado CNC de plástico PEEK: desde las ventajas del material, el proceso de mecanizado, las aplicaciones, las herramientas, hasta consejos de expertos para obtener resultados impecables. Introducción al mecanizado CNC de plástico PEEK El mecanizado CNC de plástico PEEK representa la intersección de la ciencia de los materiales y la ingeniería moderna. Este proceso libera todo el potencial de uno de los termoplásticos más avanzados del mundo, ofreciendo [...]

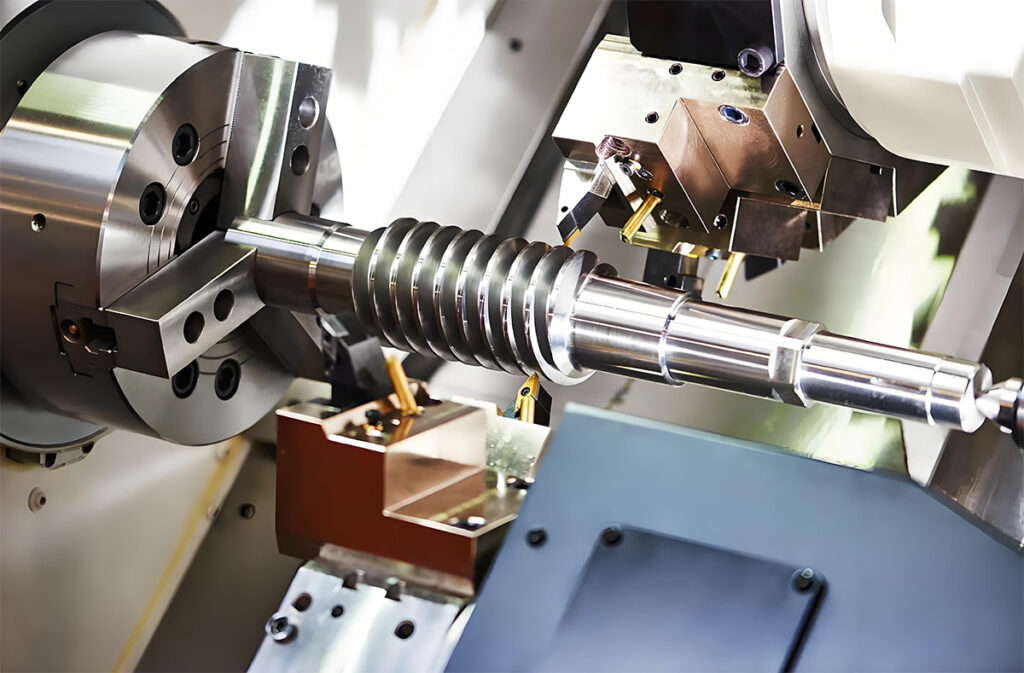

Guía del experto en mecanizado de precisión de titanio

En el centro de todos estos procesos, tecnologías y decisiones se encuentra el mecanizado de precisión del titanio: la combinación de conocimientos de ingeniería, maquinaria avanzada y operarios cualificados que convierten el titanio en bruto en piezas de misión crítica. Es un oficio que requiere paciencia, planificación y mejora continua. Tanto si se trata de fabricar un tornillo para huesos como la tobera de un cohete, la precisión es [...]

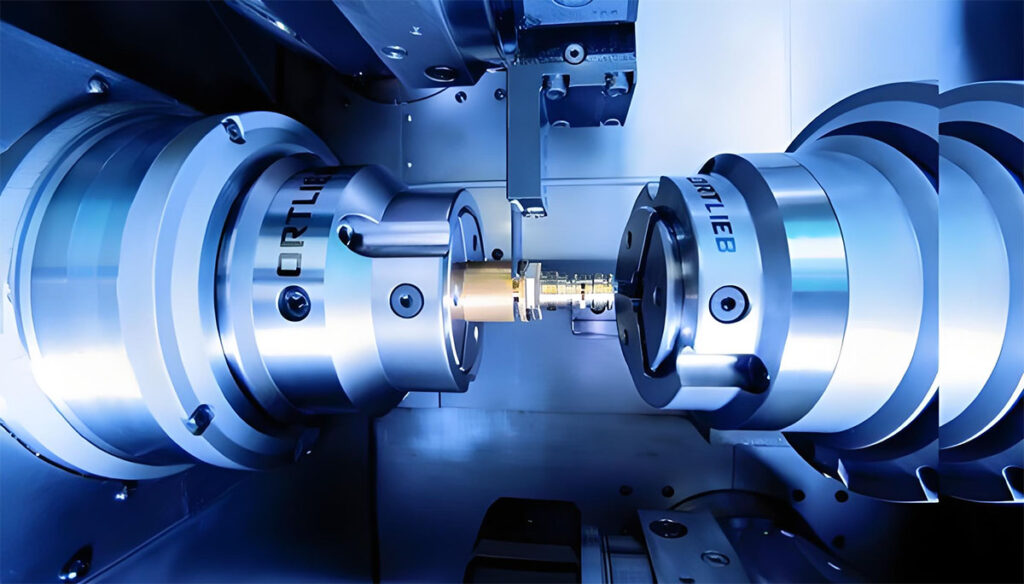

Qué es el mecanizado de piezas con husillo suizo

En el mundo de la fabricación de precisión, pocos métodos pueden igualar la precisión y versatilidad de las piezas mecanizadas con tornillos suizos. Ya se trate de un diminuto tornillo óseo para cirugía ortopédica o de un conector en una nave espacial, estas piezas son los héroes anónimos de muchas de las tecnologías de las que dependemos a diario. El mecanizado de tornillos suizos se desarrolló originalmente [...]

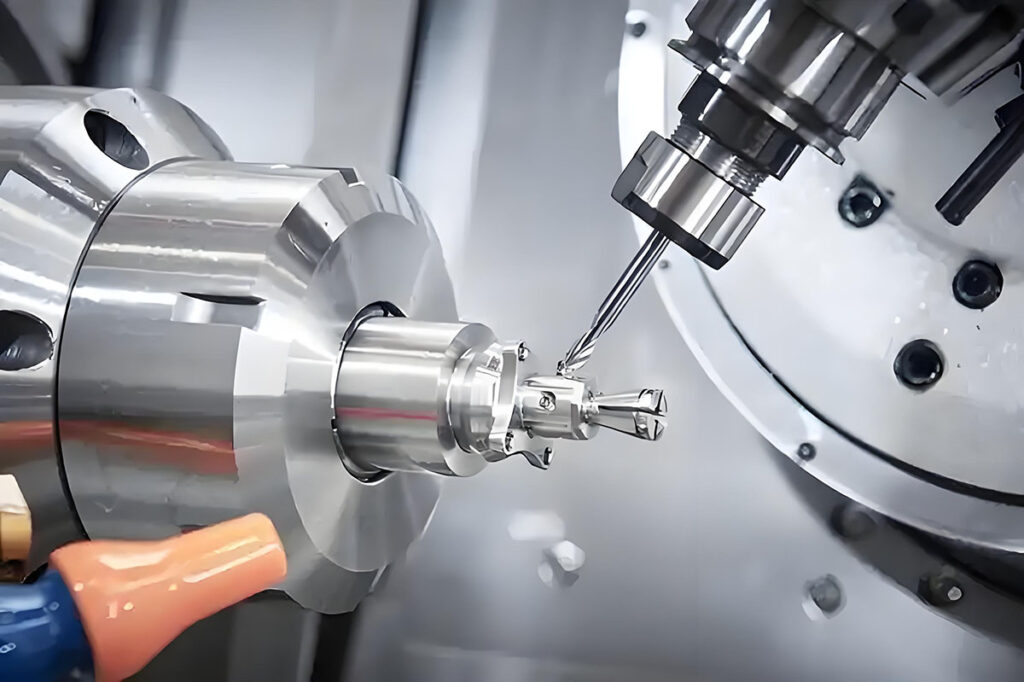

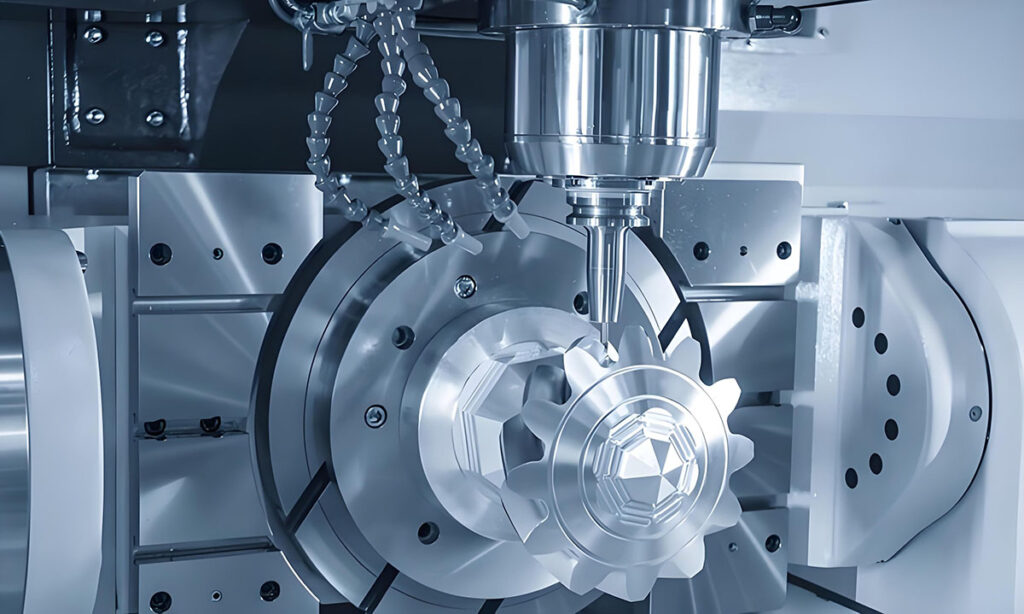

Piezas de torneado CNC multieje para la fabricación moderna

En el cambiante mundo industrial actual, la precisión lo es todo. Tanto si se trata de un pequeño tornillo médico como de un complejo accesorio aeroespacial, todas las piezas deben cumplir especificaciones estrictas. Ahí es donde entran en juego las piezas de torneado CNC multieje. Estos componentes se fabrican con máquinas avanzadas que giran y cortan desde distintos ángulos, todo de una sola vez. Esto significa menos errores, [...]

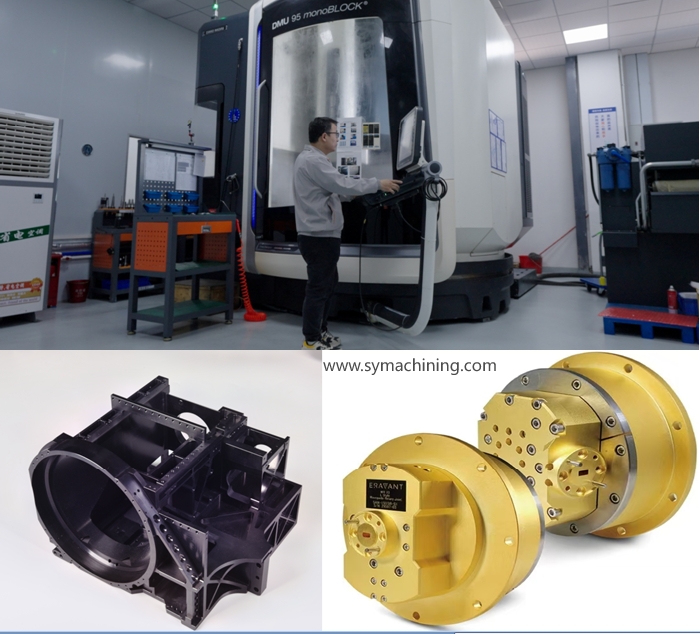

Las 10 principales ventajas de los servicios de mecanizado de precisión CNC de 5 ejes para la fabricación moderna

Descubra cómo los servicios de mecanizado de precisión CNC de 5 ejes revolucionan la producción de piezas complejas con una velocidad, precisión y versatilidad inigualables. Los fabricantes de hoy en día están bajo presión para ofrecer precisión, velocidad y eficiencia como nunca antes. Desde turbinas aeroespaciales hasta implantes médicos, la demanda de piezas complejas de alta tolerancia crece rápidamente. Ahí es donde entran en juego los servicios de mecanizado de precisión CNC de 5 ejes [...]

11 aspectos que debe conocer a la hora de elegir un proveedor de componentes mecanizados de precisión

¿Busca un proveedor fiable de componentes mecanizados de precisión? Descubra información esencial sobre calidad, materiales, certificaciones y soluciones rentables para cada sector. Introducción a los componentes mecanizados de precisión Cuando se trata de fabricar productos de alta calidad, es fundamental elegir al proveedor de componentes mecanizados de precisión adecuado. Estos proveedores suministran piezas que se utilizan en sectores como el aeroespacial, automoción, médico, [...]

Mecanizado médico ISO 13485: La norma de oro para las asociaciones de fabricantes de equipos originales

En el sector sanitario actual, altamente regulado, el mecanizado de dispositivos médicos ISO 13485 se erige como la norma de referencia para la fabricación de componentes críticos para la seguridad. Tanto si fabrica implantes ortopédicos como herramientas quirúrgicas o componentes de diagnóstico, la adhesión a la norma ISO 13485 garantiza que sus procesos de mecanizado cumplen estrictos criterios de calidad y seguridad. Esta norma mundial lo regula todo, desde la documentación y la trazabilidad hasta [...]

Servicios avanzados de mecanizado aeroespacial en China

Descubra los mejores servicios de mecanizado aeroespacial de China y compárelos con las capacidades y ventajas del sur de California. En esta completa guía, exploraremos por qué los fabricantes aeroespaciales de todo el mundo se están orientando hacia el Este, cómo se comparan las empresas chinas con sus homólogas estadounidenses y qué hace de China una elección estratégica para el suministro de componentes de precisión para aeronaves, satélites y vehículos de exploración espacial. [...]

Por qué los componentes mecanizados de calidad aeroespacial son fundamentales para el vuelo moderno

Descubra por qué los componentes mecanizados de calidad aeroespacial son vitales en las industrias aeronáutica y espacial. Conozca sus materiales, precisión y aplicaciones. Introducción a los componentes mecanizados de calidad aeroespacial Los componentes aeroespaciales no son piezas metálicas al uso. Se fabrican para condiciones extremas: altitudes, velocidades, temperaturas y expectativas extremas. Estas piezas tienen que ser increíblemente ligeras, pero también muy resistentes. Incluso las [...]

Qué es el mecanizado de precisión a medida

Descubra por qué el mecanizado de precisión a medida es esencial para una fabricación precisa, fiable y de alto rendimiento. Aprenda a elegir materiales, reducir costes y trabajar con el socio de mecanizado CNC adecuado. Introducción al mecanizado de precisión a medida El mecanizado de precisión a medida es un proceso de fabricación especializado que implica la creación de piezas o componentes altamente precisos, complejos y diseñados a medida para cumplir especificaciones exactas. [...]