Wie verpackt man effektiv Präzisionsdrehteile?

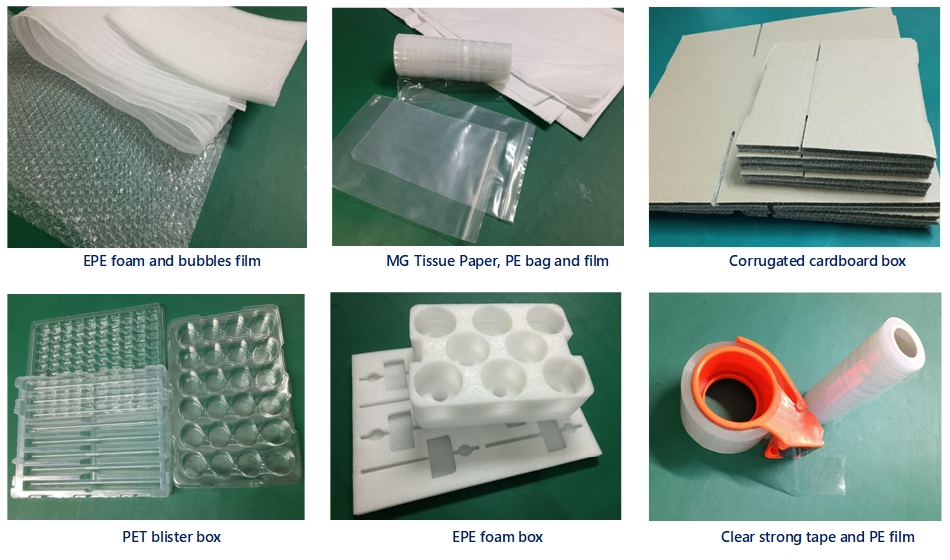

Wir bei SYM Precision Machining wissen, dass eine angemessene Verpackung für den Schutz Ihrer präzisionsbearbeiteten Teile während des Transports entscheidend ist. Um sicherzustellen, dass Ihre Produkte in perfektem Zustand am Zielort ankommen, folgen wir einem sorgfältigen Verpackungsprozess, der Material, Form und Größe der Teile berücksichtigt. Im Folgenden finden Sie unseren umfassenden Leitfaden für effektive [...]

Welche Faktoren können die Programmierzeit für CNC-Bearbeitungsprojekte beeinflussen?

Die Programmierzeit für CNC-Maschinen bei CNC-Bearbeitungsprojekten kann durch eine Vielzahl von Faktoren beeinflusst werden, darunter: 1. Komplexität der Konstruktion: Je komplexer die Geometrie des Bauteils ist, desto länger dauert es, ein effizientes und genaues CNC-Programm zu erstellen. Komplizierte Teile mit vielen Merkmalen erfordern detailliertere Anweisungen und eine sorgfältige Planung. 2. [...]

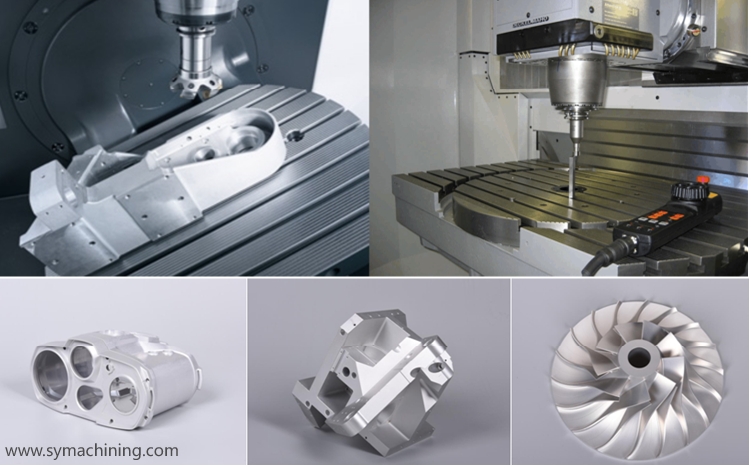

Was sind die Vorteile der 5-Achsen-CNC-Bearbeitung im Vergleich zu anderen Bearbeitungsmethoden?

Die 5-Achsen-CNC-Bearbeitung hat gegenüber der traditionellen 3-Achsen-Bearbeitung und anderen, weniger fortschrittlichen CNC-Methoden mehrere deutliche Vorteile. Hier sind einige der Vorteile, die die 5-Achsen-Bearbeitung bietet: Komplexe Geometrien: Sie kann Teile mit komplexen Geometrien in einer einzigen Aufspannung herstellen, was mit 3-Achsen-Maschinen nicht möglich ist. Reduzierte Rüstzeit: Mehrere Aufspannungen [...]

Wie Sie hochwertige CNC-Fräsdienstleistungen erhalten

Um qualitativ hochwertige CNC-Fräsdienstleistungen zu erhalten, ist es wichtig, ein seriöses CNC-Bearbeitungsunternehmen zu wählen, das über Erfahrung und Fachwissen in der von Ihnen gewünschten Art der Bearbeitung verfügt. Zu den wichtigsten Faktoren, die bei der Bewertung von CNC-Bearbeitungsdienstleistungen zu berücksichtigen sind, gehören die Bearbeitungsmöglichkeiten, die Qualitätsstandards, der Kundendienst und die Kosten. Bearbeitungskapazitäten - Das Unternehmen sollte [...]

Innovationen bei der Bearbeitung von Luft- und Raumfahrtprodukten

Erfahren Sie mehr über Bearbeitungsdienstleistungen für die Luft- und Raumfahrt in China. Jetzt mehr und mehr chinesische Fabriken können gute Präzisionsbearbeitung Dienstleistungen anbieten. SYM Präzision ist eine der Top-Bearbeitungsfabrik bekommen Innovationen in der Luft-und Raumfahrt Bearbeitungsdienstleistungen in diesen Jahren. Lassen Sie uns die folgenden Qualifikationen und Fähigkeiten zu sehen: 1. industrielle Zertifizierungen: ISO 9001 für Qualitätsmanagement-Systeme und AS9100, die [...]

Sie benötigen möglicherweise keine hochpräzise Bearbeitung

Hochpräzise Bearbeitung bedeutet nicht nur enge Toleranzanforderungen, sondern auch ein gutes Aussehen. Es geht um Konsistenz, Wiederholbarkeit und Oberflächenqualität. Dazu gehört die Herstellung von Bauteilen mit einem feinen Finish, frei von Graten oder Defekten und mit einer Detailgenauigkeit, die den hohen ästhetischen und funktionalen Standards entspricht, die in Branchen wie der Luft- und Raumfahrt, [...]

Wie lange dauert es normalerweise, ein CNC-Präzisionsbearbeitungsprojekt abzuschließen?

Der Zeitrahmen für die Fertigstellung eines CNC-Präzisionsbearbeitungsprojekts kann in Abhängigkeit von mehreren Faktoren erheblich variieren: 1. die Komplexität des Teils: Kompliziertere Konstruktionen mit engen Toleranzen können sowohl für die Programmierung der CNC-Maschinen als auch für den eigentlichen Bearbeitungsprozess zusätzliche Zeit erfordern. 2. Volumen und Chargengröße: Die Herstellung einer größeren Charge dauert länger als [...]

5 Faktoren, die den Preis von maßgefertigten Teilen beeinflussen

5 Faktoren, die den Preis von maßgefertigten Teilen beeinflussen Die Kosten für maßgefertigte Teile können in der Tat von verschiedenen Faktoren beeinflusst werden. Hier sind die fünf Faktoren, die Sie kennen sollten. 1. Das Rohmaterial: Die Art des Materials, das für das Teil benötigt wird, spielt eine wichtige Rolle bei den Kosten. Materialien wie Titan, Speziallegierungen oder [...]

Entgratungsarten für bearbeitete Teile

Es gibt viele Entgratungsarten für bearbeitete Teile. Das Entgraten ist ein wichtiger Schritt bei der Herstellung von bearbeiteten Teilen. Es handelt sich dabei um die Entfernung unerwünschter Grate, d. h. rauer Kanten oder Vorsprünge, die sich während des Fertigungsprozesses auf der Oberfläche von bearbeiteten Teilen bilden. Das Entfernen von Graten ist wichtig, weil sie die [...]

Wie Sie hochwertige CNC-Bearbeitungsdienstleistungen erhalten

4 Schlüsselfaktoren, die Sie bei der Bewertung von CNC-Bearbeitungsdienstleistungen berücksichtigen sollten. -- Bearbeitungskapazitäten -- Qualitätsstandards -- Kundenservice -- Kosten 1. Bearbeitungskapazitäten Das CNC-Bearbeitungsunternehmen sollte über die neuesten CNC-Maschinen und -Werkzeuge verfügen, um sicherzustellen, dass es enge Toleranzen und hohe Präzision für Ihre Teile erreichen kann. Das Unternehmen sollte über Erfahrung in der Bearbeitung von [...]