How to improve the productivity of hard turning?

Different machine tools for hard turning. People are increasingly demanding high quality machined parts ,and life of products.

Therefore, hardened surface .There are 2 ways to improve the productivity of hard turning.

1. Optimization Process

Previously, the preferred technology for the processing of such components is grinding, but for rotationally symmetric surface processing of flexible and cost considerations, we must choose the hard turning.

2.Tool selection

In a related aspect of the tool, cubic boron nitride (CBN) proved to be the best cutting materials, can reach Ra <2um

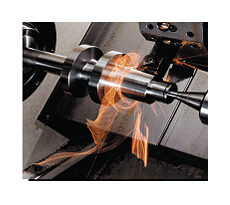

the surface quality. Feed rate can be doubled.When cutting induction hardened steel material, turning speeds of up to 120 ~ 200m / min, there will be a high temperature, CNB with a strong heat resistance, which can withstand 1,000 degrees blade edge without the risk of damage.

Under the right conditions, the lathe can also be used in hard turning. Thus, without investing a lot of money, you

can achieve a range of expansion process and respond to the new requirements of the design department. The key point is to use the right tools and the right cutting material.

Under normal circumstances, to ensure the same quality of surface conditions, can achieve double the feed rate, or in

the same processing time to achieve a higher surface quality, it can greatly improve production efficiency.